Dust Monitor

Dynoptic dust monitors use the innovative Dynamic Detection Principle (DDP) to measure dust and particulate within exhaust gases from various manufacturing processes.

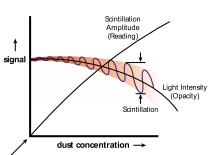

DDP, or optical scintillation as it sometimes referred to, measures the dynamic fluctuation in light transmission as dust particles move through a light beam. This dynamic fluctuation derives from temporal distributions of the dust particles which attenuate the light beam. The more dust present in the exhaust, the greater the amplitude of these fluctuations.

DDP instruments calculate the dynamic response, or the ratio of light variation to light intensity, which for particular applications, is proportional to dust concentration and when calibrated against standard reference measurements, this can be presented as a reading in mg/m3.

Unlike the standard transmission technique, DDP has immunity to gradual reductions in the absolute intensity of the light signal. Therefore, DDP instruments have the advantage that they are significantly less susceptible to drift with time, temperature or dirtying optics, than traditional opacity monitors and less sensitive to misalignment. In practice, this means that the instruments require less maintenance.

Dynoptic currently offers three different particulate monitors which each use the open path light transmission technique:

DSL-240 Dust Monitor

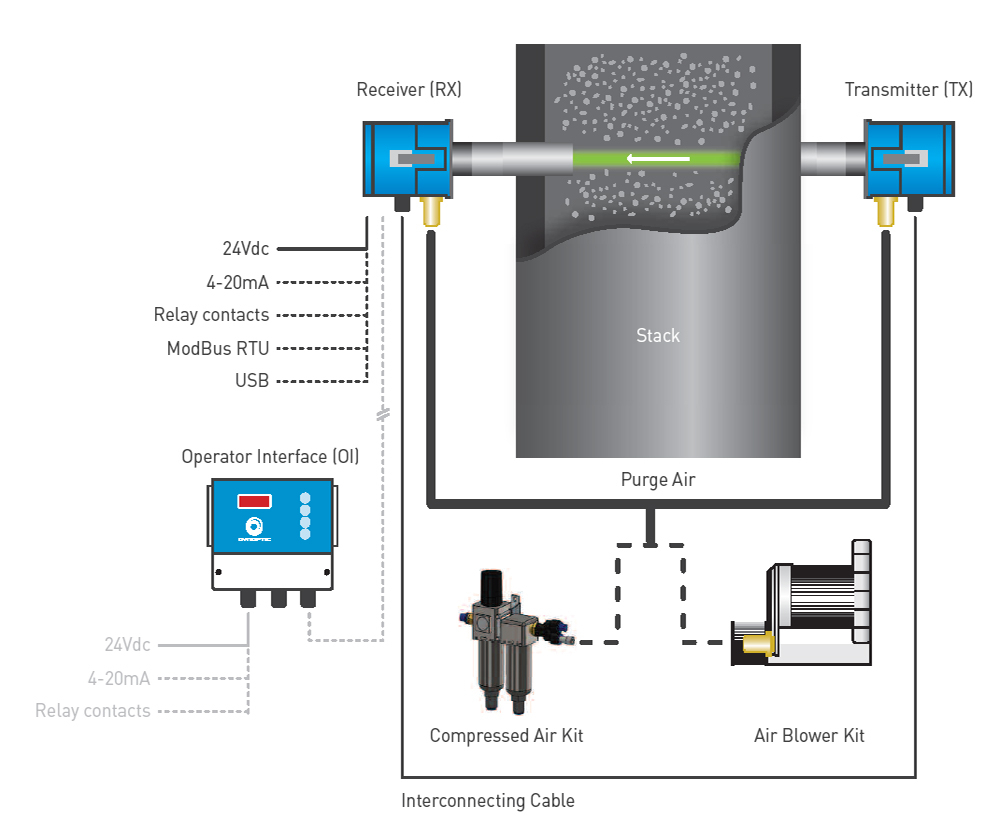

The DSL-240 Dust Monitor is an optical instrument designed to measure the concentration of dust or particulate matter in the exhaust gas passing through a duct, stack or flue.

The DSL-240 uses the innovative Dynamic Detection Principle (DDP) in which a light beam emitted from the Transmitter passes across the stack to the Receiver, which measures fluctuations in the intensity of the received light. Increased dust or particulate density in the stack causes the amplitude of these fluctuations to increase. When calibrated against standard reference measurements, the amplitude of this signal relates directly to the dust concentration in the stack and this can be presented as a reading in mg/m3.

Features

- Innovative Dynamic Detection Principle (DDP) measurement technique

- Immune to gradual reductions in absolute intensity of the light signal so less susceptible to drift

- Measurement reading as mg/m3 (when calibrated against standard reference measurements)

- Internal electronic calibration check capability

- Rugged 316 stainless steel construction

- Choice of interface options enabling easy integration

- Free utility software for PC based set-up, control and data logging

- Optional Operator Interface with different mounting configurations

Benefits

- Significantly less susceptible to drift than standard opacity monitors

- Simple to install, commission and operate with an excellent reliability record

- Rugged design with no moving parts so low maintenance

- Latched head and lid design to enable ease of access for installation and maintenance

Optional Accessories

- Operator interface (OI)

- 90-260 Vac model available

- Mounting flange installation

- Laser alignment tool to assist with installation

- Air purge blower kit (110 Vac / 230 Vac / 415 Vac

- Compressed air purge kit

- Reference filters for routine calibration check of the instrument

DSL-340 Dust Monitor

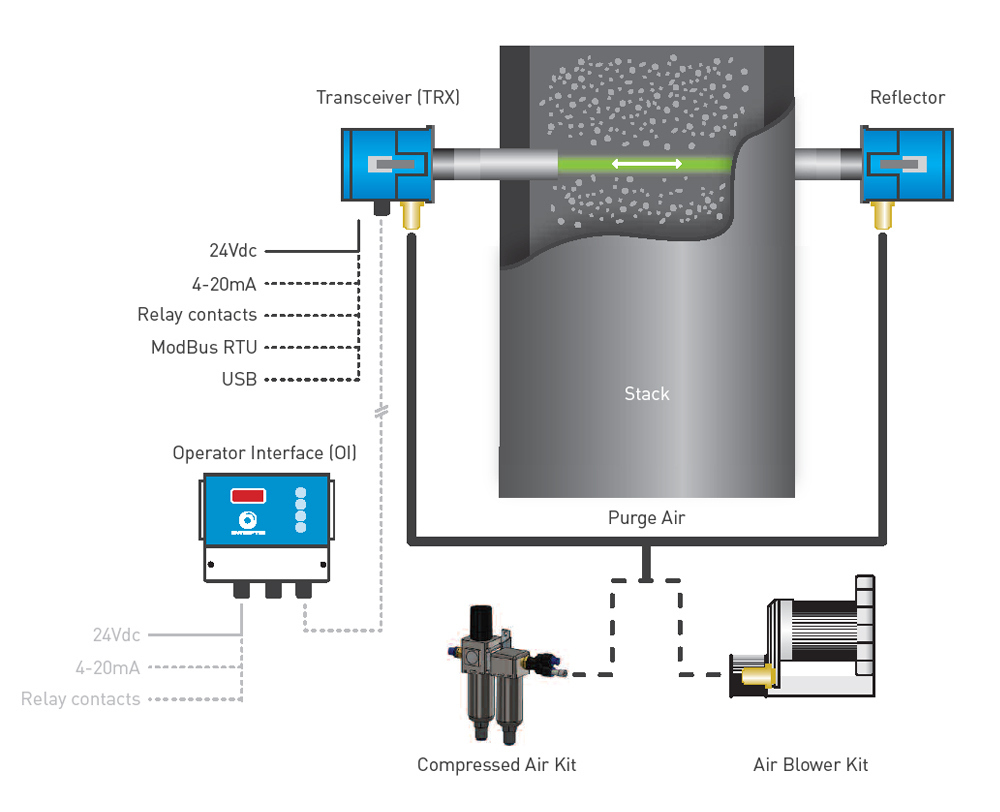

The DSL-340 Dust Monitor is an optical instrument designed to measure the concentration of dust or particulate matter in exhaust gas passing through a duct, stack or flue.

The DSL-340 uses the innovative Dynamic Detection Principle (DDP) which measures fluctuations in the intensity of a light beam, using a folded beam Transceiver/Reflector arrangement. Increased dust or particulate density in the stack causes the amplitude of these fluctuations to increase. When calibrated against standard reference measurements, the amplitude of this signal relates directly to the dust concentration in the stack and this can be presented as a reading in mg/m3

Features

- Innovative Dynamic Detection Principle (DDP) measurement technique

- Immune to gradual reductions in absolute intensity of the light signal so less susceptible to drift

- Measurement reading as mg/m³ (when calibrated against standard reference measurements)

- Internal electronic calibration check capability

- Rugged 316 stainless steel construction

- Choice of interface options enabling easy integration

- Free utility software for PC based set-up control and data logging

- Optional Operator Interface with different mounting configurations

Benefits

- Significantly less susceptible to drift than standard opacity monitors

- Better accuracy over shorter path lengths, i.e. smaller duct diameter

- Simple to install, commission and operate with an excellent reliability record

- Rugged design with no moving parts so low maintenance

- Latched head and lid design to enable ease of access for installation and maintenance

Optional Accessories

- Operator interface (OI)

- 90-260 Vac model available

- Mounting flange installation

- Laser alignment tool to assist with installation

- Air purge blower kit (110 Vac / 230 Vac / 415 Vac

- Compressed air purge kit

- Reference filters for routine calibration check of the instrument