Opacity Monitor

The history of air pollution regulation dates back as far as the 13th century when in 1273, Edward I (Longshanks) of England prohibited the burning of sea coal in London. The smoke produced by its combustion was considered detrimental to human health.

By the late 19th and early 20th centuries, regulations were being passed that sought to control air pollution predominantly for smoke and odour control. Traditionally, regulators were concerned with the visual impact of the discharge from a stack or chimney. Therefore, emission limits were expressed in terms of colour or opacity.

Modern methods for opacity measurement still use the darkness of the stack gases to measure the amount of smoke or dust emitted within the exhaust gases.

DynOptic opacity monitors use the light transmission technique to measure the visible opacity of exhaust gas in a duct, stack or flue, in which a high intensity light beam is projected across the stack. Any dust, smoke or particulate present will attenuate the transmitted light and the decrease in light intensity, due to absorption and scattering, is measured.

One advantage of opacity systems is that they are insensitive to interference from other flue gas components since the beam spectrum is within the photopic region (400-700 nm) and most other flue gas constituents do not absorb in this spectral region.

There are two types of opacity monitors; Single Pass and Double Pass.

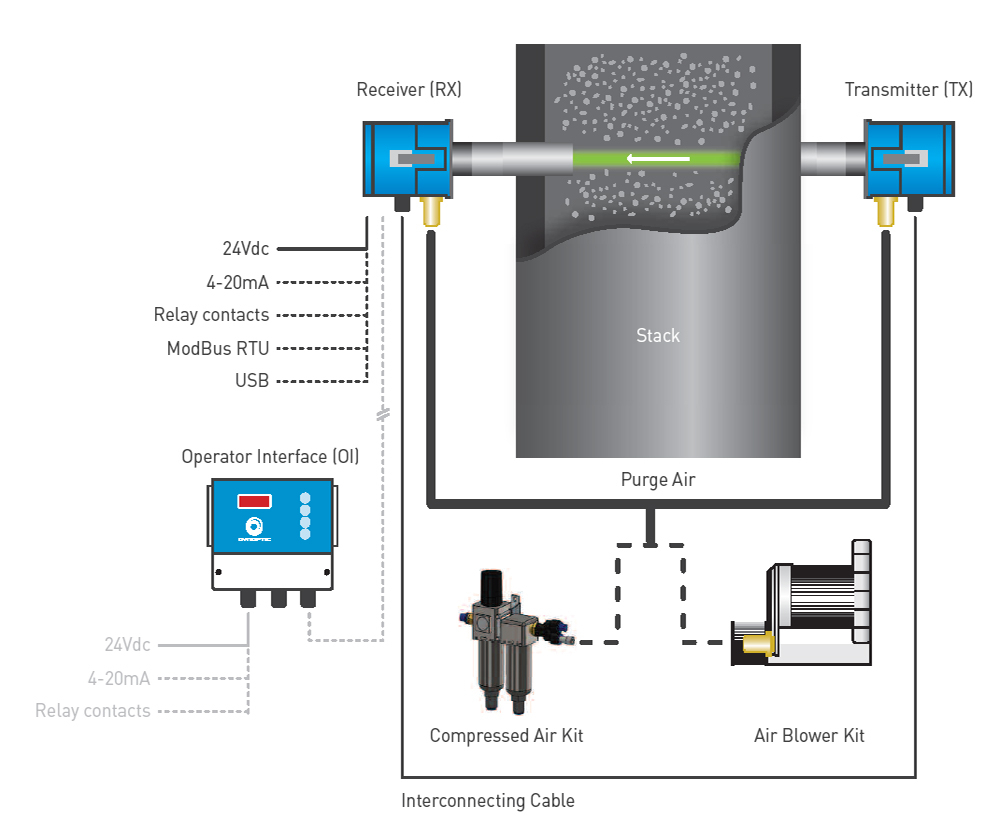

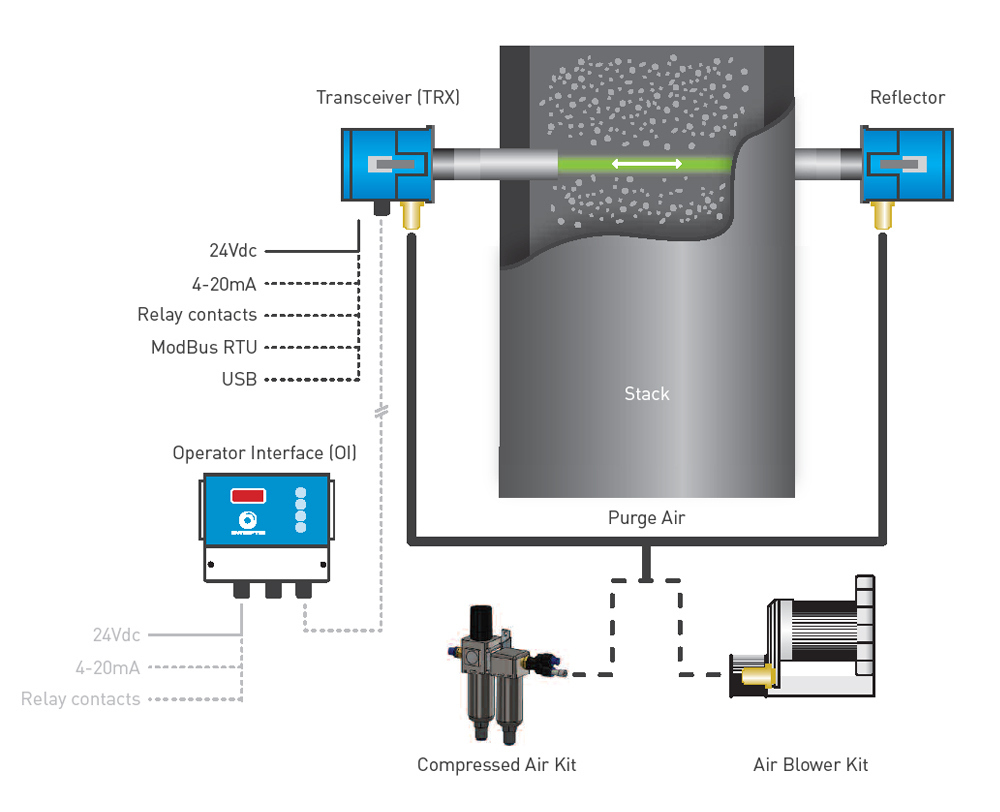

Single pass opacity monitors have a Transmitter/Receiver arrangement with the light beam emitted from the Transmitter passing across the stack to a Receiver. Double pass opacity monitors have a folded beam Transceiver/Reflector arrangement with the light beam emitted from the Transceiver (TRX) passing across the duct to a Reflector, which then returns the light to the Transceiver.

Single pass opacity monitors are the simplest type of instrument and offer a very cost effective solution to meet monitoring requirements. One advantage to single pass systems is that they are suitable for applications with long path lengths, i.e. large stack diameters and DynOptic single pass opacity monitors can be used for path lengths of up to 20m.

Double pass systems are more suited to continuous emission monitoring as they have a number of advantages over single pass systems in that:

- Double pass opacity monitors have better sensitivity at smaller duct diameters

- Double pass opacity monitors are simpler to install as electrical services are only required to one side of the stack

- Double pass opacity monitors allow for an in-situ zero and calibration facility

DynOptic currently offers three different opacity monitors:

DSL-220 Opacity Monitor

The DSL-220 Opacity Monitor is an optical instrument designed to measure the visible opacity of exhaust gas in a duct, stack or flue.

The DSL-220 uses the single pass light transmission measurement technique, with Transmitter/Receiver arrangement. A light beam emitted from the Transmitter passes across the stack to a Receiver, which measures the intensity of the received light. Increased particulate or smoke density in the stack gas attenuates the transmitted light and causes the intensity of the received light to fall. This reduction in intensity is measured and presented as % opacity. The higher the level of particulate or smoke present, the more light lost and therefore, the greater the opacity.

Features

- In situ measurement directly in exhaust gas flow

- Measurement reading as % Opacity

- Modulated green LED source for long lifetime stability and immunity to ambient light

- Rugged 316 stainless steel construction

- Choice of interface options enabling easy integration

- Free utility software for PC based set-up control and data logging

- Optional Operator Interface with different mounting configurations

Benefits

- Low cost

- Simple to install, commission and operate with an excellent reliability record

- Rugged design with no moving parts so low maintenance

- Latched head and lid design to enable ease of access for installation and maintenance

Optional Accessories

- Operator interface (OI)

- 90-260 Vac model available

- Mounting flange installation kit

- Laser alignment tool to assist with installation

- Air purge blower kit (110 Vac / 230 Vac / 415 Vac

- Compressed air purge kit

- Reference filters for routine calibration check of the instrument

DSL-320 Opacity Monitor

The DSL-320 Opacity Monitor is an optical instrument designed to measure the visible opacity of exhaust gas in a duct, stack or flue.

The DSL-320 uses the double pass light transmission measurement technique, with a folded beam Transceiver/Reflector arrangement. A light beam emitted from the Transceiver (TRX) passes across the duct, stack or flue to a Reflector, which then returns the light to the Transceiver where the intensity of the received light is measured. Increased particulate or smoke density in the stack gas attenuates the transmitted light and causes the intensity of the received light to fall. This reduction in intensity is measured and presented as % opacity. The higher the level of particulate or smoke present, the more light lost and therefore, the greater the opacity.

Features

- In situ measurement directly in exhaust gas flow

- Measurement reading as % Opacity

- Modulated green LED source for long lifetime stability and immunity to ambient light

- Rugged 316 stainless steel construction

- Choice of interface options enabling easy integration

- Free utility software for PC based set-up control and data logging

- Optional Operator Interface with different mounting configurations

Benefits

- Simpler installation than single pass opacity monitors

- Better accuracy over shorter path lengths than single pass opacity monitors

- Rugged design with no moving parts so low maintenance

- Latched head and lid design to enable ease of access for installation and maintenance

Optional Accessories

- Operator interface (OI)

- 90-260 Vac model available

- Mounting flange installation kit

- Laser alignment tool to assist with installation

- Air purge blower kit (110 Vac / 230 Vac / 415 Vac

- Compressed air purge kit

- Reference filters for routine calibration check of the instrument

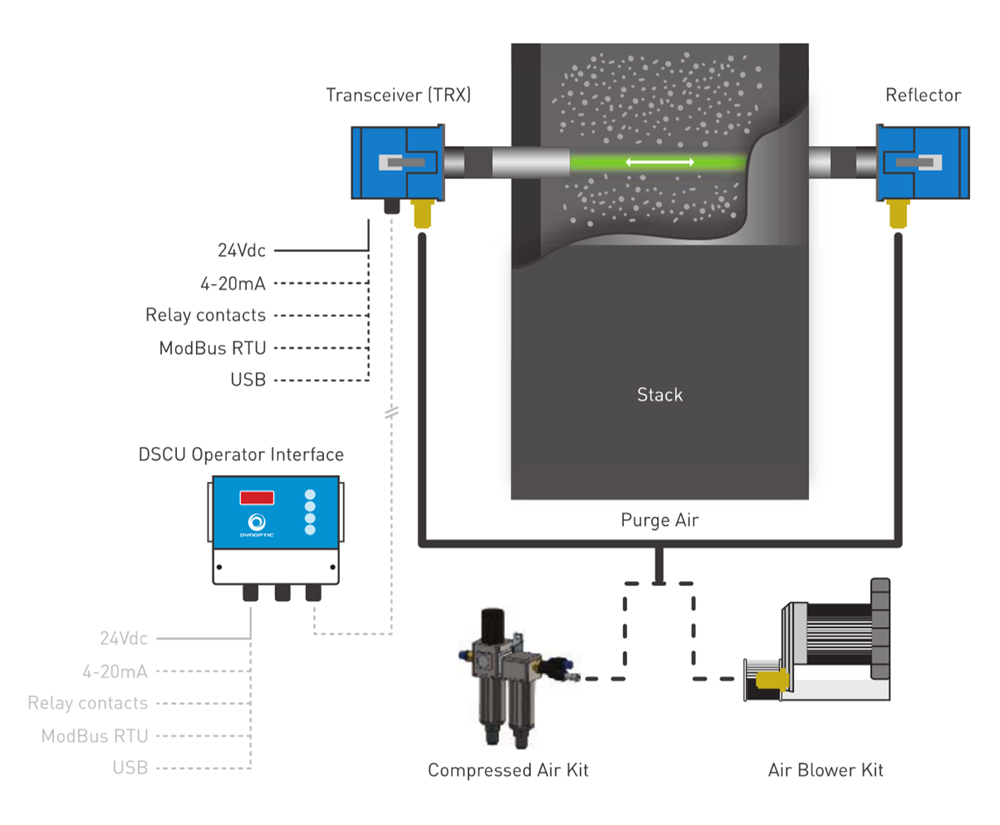

DSL-460 Particulate/Opacity Monitor

The DSL-460 Particulate/Opacity Monitor is an optical instrument designed to measure the visual opacity and/or concentration of dust or particulate matter in an exhaust gas passing through a duct, stack or flue.

The DSL-460 uses the double pass light transmission measurement technique, with a folded beam Transceiver/Reflector arrangement. A light beam emitted from the Transceiver (TRX) passes across the duct, stack or flue to a Reflector, which then returns the light to the Transceiver where the intensity of the received light is measured. Increased particulate density in the stack gas attenuates the transmitted light and causes the intensity of the received light to fall. This reduction in intensity can be presented as % opacity or when calibrated against standard reference measurements, this reduction in intensity can be used to calculate the particulate concentration and present a reading in mg/m3.

Features

- In situ measurement directly in exhaust gas flow

- Measurement reading as % opacity and/or particulate as mg/m3

- Modulated green LED source for long lifetime stability and immunity to ambient light

- Rugged 316 stainless steel construction

- Integrated visual alignment aid to simplify installation

- In-situ zero and calibration check facility

- Intelligent’ sensor with optional DSCU operator interface with dual parameter display

- Choice of interface options enabling easy integration

Benefits

- Plug and socket connectors for ease of installation

- Simpler installation than single pass opacity monitors with better accuracy over shorter path lengths

- Rugged design with no moving parts so low maintenance

- Latched head and lid design to enable ease of access for installation and maintenance

Optional Accessories

- DSCU operator Interface with dual parameter display

- 90-260 Vac model available

- Mounting flange installation kit

- Laser alignment tool to assist with installation

- Air purge blower kit (110 Vac / 230 Vac / 415 Vac

- Compressed air purge kit

- Reference filters for routine calibration check of the instrument

- External weather covers for TRX and Reflector heads