Particulate Monitor

With the advent of specific process emission limits being defined, continuous particulate monitoring has become a regulatory requirement for many industries.

Particulate monitoring requires the measurement of the mass concentration of particulate matter in stack emissions to atmosphere. There is no known method of continuously measuring particulate concentration by direct measurement and therefore, all continuous particulate measurement methods are inferential.

Each method involves the measurement of a parameter related to particulate concentration and then requires a calibration to be determined to convert the measured value into one of particulate mass concentration.In order to output particulate concentration in mg/m3, a Density Scale Factor (DSF) must be determined. The Density Scale Factor for any given installation will vary based on the type, shape, size and colour of the particles in the gas stream and therefore, the Density Scale Factor must be determined on site, through comparison of the instrument readings with an independent reference measurement*.

During normal operation:

Particulate concentration (mg/m3) = measured parameter x DSF

*It is recommended that standard reference measurement is made using gravimetric analysis based on isokinetic sampling of the gas stream such as EN13284-1:2002 or For further information about any of our products please call or e-mail and a member of our team will be happy to help. Dynoptic currently offers three different particulate monitors which each use the open path light transmission technique:

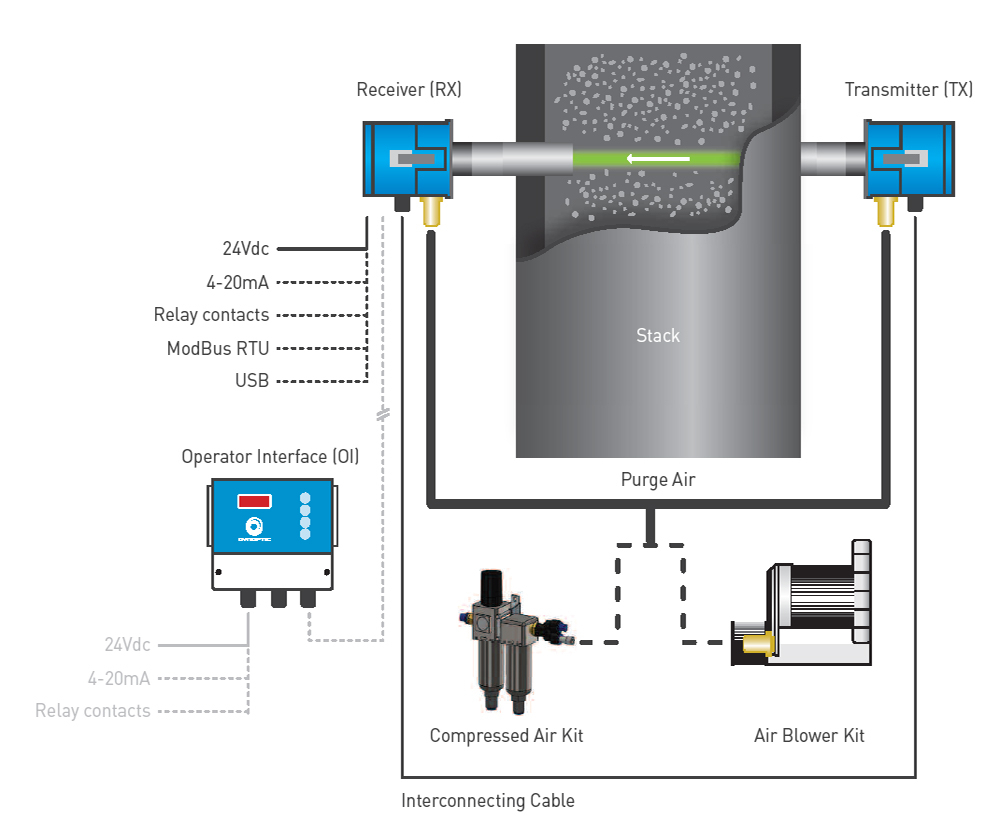

DSL-230 Particulate Monitor

The DSL-230 Particulate Monitor is an optical instrument designed to measure the concentration of dust or particulate matter in an exhaust gas passing through a duct, stack or flue

The DSL-230 uses the single pass light transmission measurement technique, with Transmitter/Receiver arrangement. A light beam emitted from the Transmitter passes across the stack to a Receiver, which measures the intensity of the received light. Increased particulate density in the stack gas attenuates the transmitted light and causes the intensity of the received light to fall. When calibrated against standard reference measurements, this reduction in intensity can be used to calculate the particulate concentration and present a reading in mg/m3.

Features

- In situ measurement directly in exhaust gas flow

- Measurement reading as mg/m3 (when calibrated against standard reference measurements)

- Modulated green LED source for long lifetime stability and immunity to ambient light

- Rugged 316 stainless steel construction

- Choice of interface options enabling easy integration

- Free utility software for PC based set-up control and data logging

- Optional Operator Interface with different mounting configurations

Benefits

- Low cost

- Simple to install, commission and operate with an excellent reliability record

- Rugged design with no moving parts so low maintenance

- Latched head and lid design to enable ease of access for installation and maintenance

Optional Accessories

- Operator interface (OI)

- 90-260 Vac model available

- Mounting flange installation

- Laser alignment tool to assist with installation

- Air purge blower kit (110 Vac / 230 Vac / 415 Vac

- Compressed air purge kit

- Reference filters for routine calibration check of the instrument

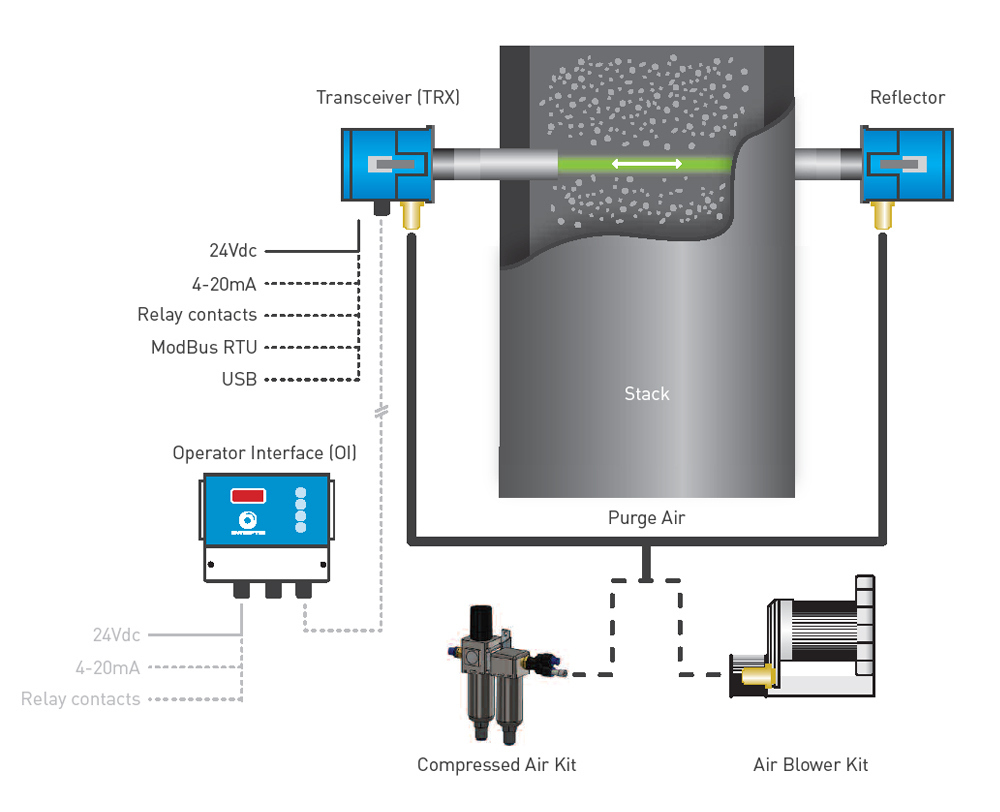

DSL-330 Particulate Monitor

The DSL-320 Opacity Monitor is an optical instrument designed to measure the visible opacity of exhaust gas in a duct, stack or flue.

The DSL-330 uses the double pass light transmission measurement technique, with a folded beam Transceiver/Reflector arrangement. A light beam emitted from the Transceiver (TRX) passes across the duct, stack or flue to a Reflector, which then returns the light to the Transceiver where the intensity of the received light is measured. Increased particulate density in the stack gas attenuates the transmitted light and causes the intensity of the received light to fall. When calibrated against standard reference measurements, this reduction in intensity can be used to calculate the particulate concentration and present a reading in mg/m3

Features

- In situ measurement directly in exhaust gas flow

- Measurement reading as mg/m3 (when calibrated against standard reference measurements)

- Modulated green LED source for long lifetime stability and immunity to ambient light

- Rugged 316 stainless steel construction

- In-situ zero and calibration check facility

- Choice of interface options enabling easy integration

- Free utility software for PC based set-up control and data logging

- Optional Operator Interface with different mounting configurations

Benefits

- Simpler installation than single pass opacity monitors

- Better accuracy over shorter path lengths than single pass opacity monitors

- Rugged design with no moving parts so low maintenance

- Latched head and lid design to enable ease of access for installation and maintenance

Optional Accessories

- Operator interface (OI)

- 90-260 Vac model available

- Mounting flange installation

- Laser alignment tool to assist with installation

- Air purge blower kit (110 Vac / 230 Vac / 415 Vac

- Compressed air purge kit

- Reference filters for routine calibration check of the instrument

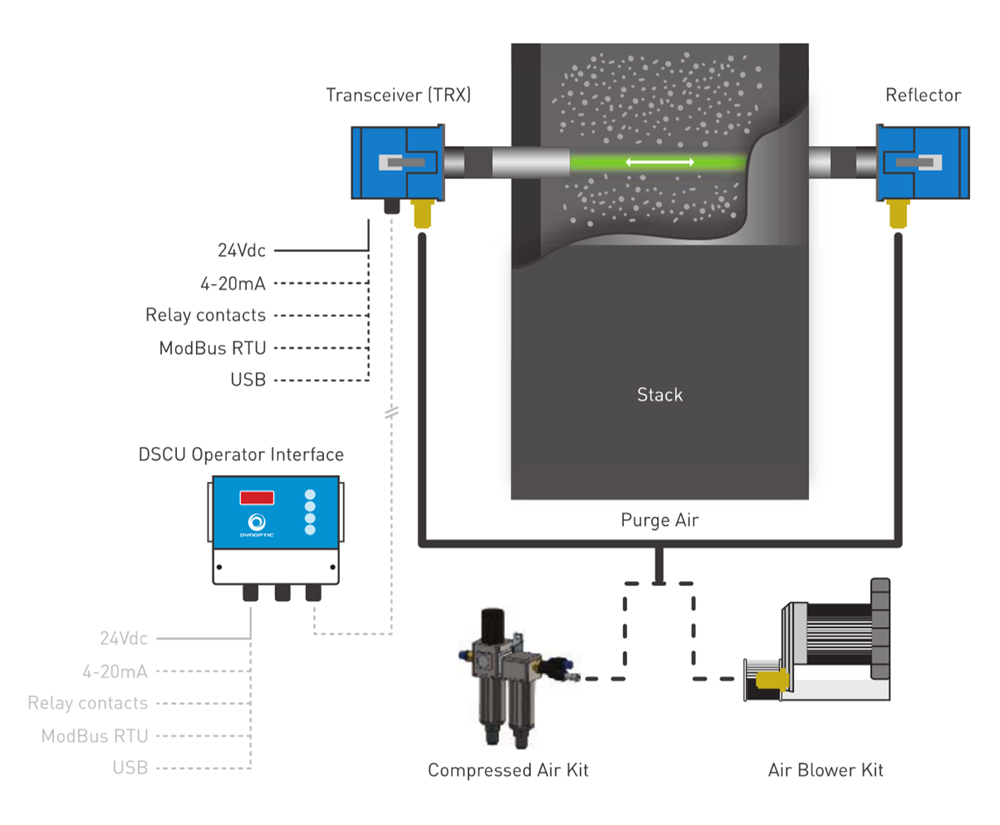

DSL-460 Particulate Monitor

The DSL-460 Particulate Monitor is an optical instrument designed to measure the visual opacity and/or concentration of dust or particulate matter in an exhaust gas passing through a duct, stack or flue.

The DSL-460 uses the double pass light transmission measurement technique, with a folded beam Transceiver/Reflector arrangement. A light beam emitted from the Transceiver (TRX) passes across the duct, stack or flue to a Reflector, which then returns the light to the Transceiver where the intensity of the received light is measured.

Increased particulate density in the stack gas attenuates the transmitted light and causes the intensity of the received light to fall. This reduction in intensity can be presented as % opacity or when calibrated against standard reference measurements, this reduction in intensity can be used to calculate the particulate concentration and present a reading in mg/m3.

Features

- In situ measurement directly in exhaust gas flow

- Measurement reading as % opacity and/or particulate as mg/m3

- Modulated green LED source for long lifetime stability and immunity to ambient light

- Rugged 316 stainless steel construction

- Integrated visual alignment aid to simplify installation

- In-situ zero and calibration check facility

- 'Intelligent' sensor with optional DSCU operator interface with dual parameter display

- Choice of interface options enabling easy integration

Benefits

- Plug and socket connectors for ease of installation

- Simpler installation than single pass opacity monitors with better accuracy over shorter path lengths

- Rugged design with no moving parts so low maintenance

- Latched head and lid design to enable ease of access for installation and maintenance

Optional Accessories

- DSCU operator Interface with dual parameter display

- 90-260 Vac model available

- Mounting flange installation

- Laser alignment tool to assist with installation

- Air purge blower kit (110 Vac / 230 Vac / 415 Vac

- Compressed air purge kit

- Reference filters for routine calibration check of the instrument

- External weather covers for TRX and Reflector heads

DSL-610

The DSL-610 is an optical instrument designed to measure the concentration of particulate matter in an exhaust gas passing through a duct, stack or flue; typically the exhaust gas from an industrial combustion process or air filtration system.

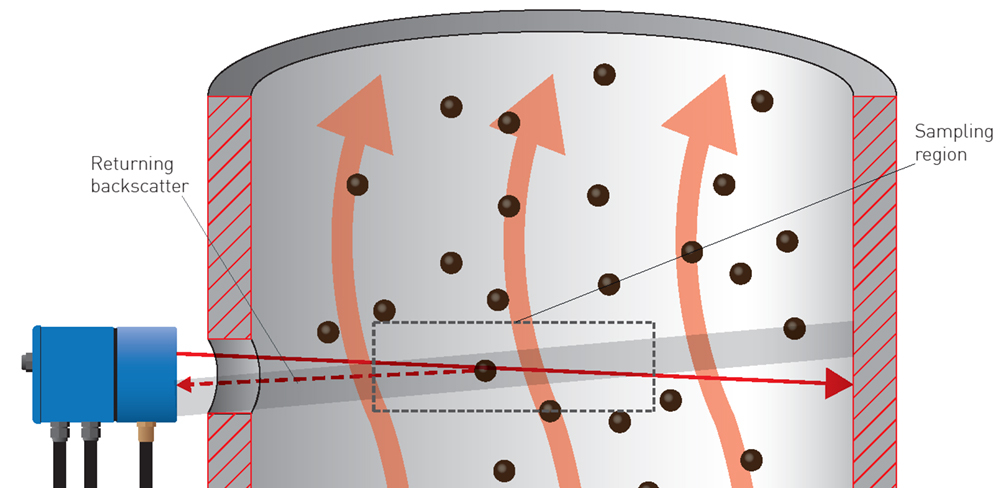

The DSL-610 Backscatter Monitor uses the laser backscatter measurement technique to measure particulate, dust and smoke emissions. The DSL-610 consists of a single Transceiver (TRX) head that is mounted on one side of the stack only. The TRX head emits a beam of laser light into the stack and any light backscattered from suspended particles is detected by the TRX. In creased particulate density in the stack gas produces an increase in the level of the scattered light. When calibrated against a standard reference measurement, the measured backscattered light can be used to calculate the particulate.

Features

- In situ measurement directly in exhaust gas flow

- Measurement reading as mg/m (when calibrated against standard reference measurements)

- Rugged 316 stainless steel construction

- Laser backscatter method requires no alignment and only a single access port on the stack

- 'Intelligent’ sensor with optional DSCU operator interface with dual parameter display

- Choice of interface options enabling easy integration

Benefits

- Plug and socket connectors for ease of installation

- Simpler installation than single pass opacity monitors with better accuracy over shorter path lengths

- Rugged design with no moving parts so low maintenance

- Latched head and lid design to enable ease of access for installation and maintenance