Twin-Tek News

2026

26th February 2026 - Rising Carbon Costs Drive The Need For Accurate Emissions Management In European Shipping

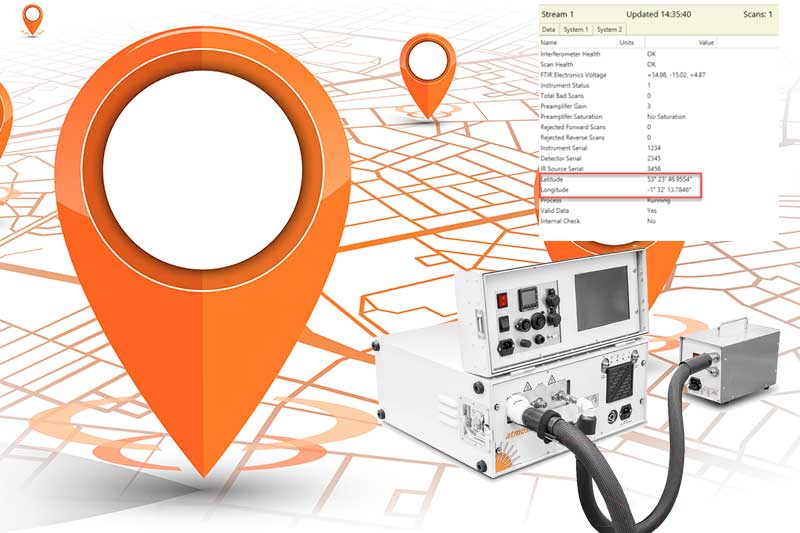

Owners and operators of vessels over 5,000 GT trading in Europe now face significantly increased compliance costs following the full implementation of the EU Emissions Trading System (EU ETS).

From 1 January, the transition phase ended and shipping entered full scope. This has increased fuel-related costs by around $100 per tonne for high and low sulphur fuel oil and marine gasoil, on top of the approximately $200 per tonne already associated with EU ETS Allowances. As a result, carbon exposure has become a material operational cost that must be actively managed rather than simply absorbed.

Under the updated framework, vessels operating entirely within EU/EEA waters must now surrender Allowances covering 100% of their carbon emissions. In addition, reporting obligations extend beyond CO2 to include methane (CH4) and nitrous oxide (N2O), further increasing compliance complexity. Ships trading in and out of the region must purchase allowances covering 50% of voyage emissions, while fuel consumed at EU/EEA ports must be fully accounted for.

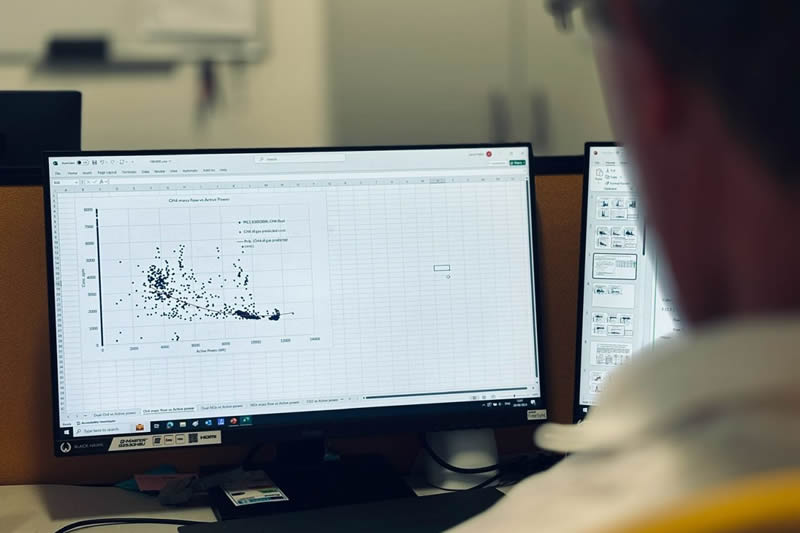

In this environment, accurate and transparent emissions measurement is critical. Reliance solely on fuel consumption calculations can expose operators to the risk of over-reporting emissions and purchasing more Allowances than necessary. Direct CO2 measurement and real-time emissions monitoring provide a more precise, verifiable method of quantifying actual exhaust emissions. This supports stronger MRV (Monitoring, Reporting and Verification) compliance, reduces the risk of discrepancies, and may identify opportunities to lower Allowance requirements.

By implementing certified, traceable emissions measurement systems, operators can improve reporting confidence, optimise fuel efficiency, and potentially reduce their overall ETS exposure. With carbon costs now directly impacting voyage economics, proactive emissions management is becoming a key commercial and technical priority for shipowners trading in European waters.

Full compliance with the EU Emissions Trading System (EU ETS) has significantly increased the cost of burning very low sulphur fuel oil on voyages within EU waters. Although the exact impact varies with carbon allowance prices and exchange rates, the added expense has made fuel efficiency a critical commercial priority.

Even minor combustion inefficiencies, such as poor ignition timing, uneven cylinder loads or injector wear, can gradually increase fuel consumption without triggering immediate alarms. Under the EU ETS, every extra tonne of fuel burned requires additional carbon allowances, directly raising operating costs. As a result, optimising engine performance and closely managing emissions are now essential to controlling compliance costs and protecting voyage profitability.

#Protea #EmissionsMonitoring #CEMS #FTIR #GasAnalysers #ShippingEmissions #MarineEmissions #CarbonCapture #CCUS

Read More16th January 2026 - Carbon Capture Utilisation & Storage (CCUS) In 2026

Here are the five key areas to watch for in Carbon Capture, Utilisation and Storage (CCUS) in 2026 with critical indicators of how the sector could evolve this year and shape decarbonisation strategies globally.

- Scale-Up from Pilot to Gigaton-Scale Projects

- The CCUS industry is trying to move beyond isolated demonstration projects toward interconnected, gigaton-scale carbon management ecosystems. This transition involves boosting capture and storage capacity dramatically — the industry currently has growth in projects planned up to 2030 but is still far below what’s needed for climate goals.

- Why it matters: Success here will determine whether CCUS becomes material to global emissions reductions or remains a niche solution.

- Development of CO2 Infrastructure & Hub Models

- Shared transport and storage infrastructure (hub models) is becoming essential to make CCUS cost-effective and viable at scale. Connecting emitters to shared pipelines and permanent geological storage (e.g., saline aquifers or depleted oil/gas fields) can distribute risk and reduce costs.

- Watch for in 2026 with Major hub announcements (e.g., North Sea, Gulf regions) and Policy frameworks enabling cross-industry CO2 transport & storage.

- Technological Innovation & Cost Reduction

- Several emerging technologies and optimization strategies are gaining momentum.

- Advanced capture materials & AI-assisted solvent discovery to lower energy use and CAPEX/OPEX.

- AI and machine learning to optimize operations and performance.

- Novel capture approaches (e.g., solar-driven processes) are gaining industry attention.

- Why it matters: Cost reduction and performance gains are critical to wider deployment — and will influence investment flows in 2026.

- Policy & Incentive Frameworks

- Government policy — including subsidies, tax credits, carbon pricing and R&D roadmaps — remains a key driver for CCUS deployment. Several national initiatives are underway (e.g., India’s CCUS R&D roadmap to 2070 net-zero goals).

- To watch in 2026: New or expanded CCUS incentives in major markets (US, Europe, Asia) and Changes in carbon pricing regimes affecting project economics.

- Industrial Adoption Beyond Fossil Fuels

- While oil and gas companies still dominate CCUS capacity, hard-to-abate sectors like cement, steel and chemicals are ramping up interest — especially where decarbonisation options are limited or high-cost without CCUS.

- Implications for 2026: First commercial CCUS retrofits in heavy industry Emerging utilisation pathways (e.g., fuels, chemicals) and Increased integration with hydrogen and low-carbon energy systems.

During 2026, it should become clear whether CCUS can scale meaningfully to support climate targets, how infrastructure development and policy frameworks evolve to reduce costs and unlock new projects, which emerging technologies achieve commercial traction, and whether major industrial emitters and markets adopt CCUS beyond early movers. At the same time, ongoing criticism around cost, climate accountability and effectiveness, particularly concerns that CCUS may prolong fossil fuel use, will continue to influence investor confidence, policy direction and public support in key regions.

#Protea #EmissionsMonitoring #CEMS #FTIR #GasAnalysers #ShippingEmissions #MarineEmissions #CarbonCapture #CCUS

Read More2025

1st December 2025 - Global Underground CO2 Storage Data Offers Hope Amid Rising Emissions

Scientists have, for the first time, published a comprehensive record of how much carbon dioxide (CO2) has been permanently stored underground worldwide using carbon capture and storage (CCS). The new report from the London Register of Subsurface CO2 storage shows that since 1996 over 383 million tonnes of CO2 have been safely sequestered, roughly equivalent to taking 81 million cars off the road for a year.

A proven, global carbon-management effort. This milestone is not just a hopeful statistic with its evidence that CCS is already working at scale. The storage comes mainly from large projects in the United States, China, Brazil, Australia, and the Middle East, with continued expansion expected through 2024–2025. The report’s authors argue that CCS shouldn’t be viewed as a futuristic or speculative technology, but rather as a proven and scalable tool that can play a real role today in reducing atmospheric CO2.

The initiative is led by researchers at Imperial College London, collaborating with academic and industry partners globally, including institutions such as Stanford University, MIT, the Global CCS Institute, the Carbon Capture & Storage Association, IEAGHG, and CSIRO in Australia. According to Samuel Krevor, Director of the Register, this report “demonstrates a proven capability and accelerating momentum for geologic storage of CO2”. “We have found that industrial-scale carbon management is already a reality and can safely sequester CO2 deep underground, which will be a key strategy, alongside vital efforts to cut emissions, for decarbonising hard-to-abate industries and cutting the total CO2 in the atmosphere.”

How CCS works and why it matters

CCS operates by capturing CO2 emitted from power plants and industrial processes, then injecting it deep underground (commonly 1 km or more) where it is securely trapped in geological formations such as depleted oil and gas reservoirs. This makes CCS especially important for sectors that cannot easily shift to renewable electricity, for example, heavy industry like steel or cement production. Many international bodies, including the Intergovernmental Panel on Climate Change (IPCC), consider CCS a critical tool for achieving net-zero emissions.

Rapid growth in recent years - The new report identifies three broad phases of CCS growth:

- 1996–2007 ("Pioneering Phase") - when geological storage was first demonstrated as technically feasible.

- 2008–2015 ("North American Expansion") - when the number of storage sites increased significantly, proving injection worked on a larger scale.

- 2016–2023 ("Global Scaling") - when CCS deployment spread globally and storage rates surged.

In 2023 alone, CCS projects stored a record 45.2 million tonnes of CO 2, an increase of 8.4 million tonnes compared with the previous year. Leading projects include the Seminole San Andres Unit in the US (3.9 MtCO 2 in 2023) and the Santos Basin Pre-Salt oilfield in Brazil (13.0 MtCO 2 in 2023). Together, they accounted for more than a third of all CO 2 stored that year. Although data from 2024 remain incomplete, early indicators point to sustained, perhaps growing, CO 2 storage, especially in regions such as Brazil and China. To give a sense of scale: the CO 2 stored in 2023 alone roughly corresponds to the emissions avoided by all renewable energy produced in Australia or Italy that year, or to two thirds of the UK’s renewable-generated emissions avoided in the same period.

The road ahead: what’s needed for climate goals. Despite these encouraging numbers, researchers say much more must be done to reach climate targets. To keep global warming under 1.5 °C, projections suggest storage must scale up dramatically, to at least 1 billion tonnes (a gigatonne) per year by 2050.

The authors emphasise that while CCS is a powerful tool, it should work alongside, not instead of, deep cuts in emissions from energy and industry. CCS can help decarbonise sectors that are difficult to electrify, but the fundamental challenge remains reducing emissions overall. They also argue that renewed policy support and investment will be crucial. As more CCS projects come online, costs are likely to fall, just as they have done in other decarbonisation technologies.

A call for collaboration and commitment

The Register’s global consortium, spanning academia, industry, and government, shows how international cooperation can accelerate deployment of carbon-storage infrastructure. Given the urgency of climate change and the limitations of emission reductions alone, the success of CCS to date offers a “hopeful message”: the technology to capture and store CO 2 at scale already exists, and with determination, policy support, and continued collaboration, it can significantly contribute to the global fight against climate change.

#Protea #Emissions #Monitoring #CEMS #FTIR #Gas #Analysers #Shipping #Marine #Carbon #Capture

Read More4th November 2025 - IMO Postpones Adoption Of Global Net-Zero Shipping Framework

The International Maritime Organization (IMO) has postponed the adoption of its landmark Net-Zero Framework (NZF) for global shipping by one year, following a contentious vote at the Marine Environment Protection Committee’s (MEPC) extraordinary session in London.

The NZF was intended to establish a global fuel standard, a greenhouse-gas pricing system, and an IMO-managed Net-Zero Fund to finance decarbonisation and support developing countries. The framework was expected to be adopted in 2025 and take effect in 2027, but the vote has been deferred until October 2026.

The motion to delay, introduced by Singapore and formally submitted by Saudi Arabia, passed with 57 votes in favour, 49 against, and 21 abstentions. Supporters cited the need for more time to refine technical details and build consensus among developing states. Opponents warned the delay weakens global climate momentum and creates uncertainty for shipowners planning green investments.

Diplomatic tensions ran high during the meeting. Reports indicated that the United States and other major economies lobbied against the NZF’s emissions-pricing component, prompting accusations of “undiplomatic pressure” on smaller nations. IMO Secretary-General Arsenio Domínguez called the session “unusual” and urged delegates to return to constructive dialogue.

The postponement means regional climate rules such as the EU Emissions Trading System (EU-ETS) and FuelEU Maritime, will continue to shape decarbonisation efforts in the interim. Industry and environmental groups have expressed concern that fragmented regulations could complicate compliance and delay investment in zero-emission technologies.

Technical work on the NZF will continue through 2026, with member states expected to resume negotiations next October. The delay marks a setback for global shipping’s net-zero ambitions, but IMO officials insist the framework remains “on course, though with a longer horizon.” Find out more about the activities of Marine Emissions monitoring systems from Protea and the need to demonstrate environmental responsibility which is key for today’s marine and offshore industries at https://www.protea.ltd.uk/marine.

#Protea #Emissions #Monitoring #CEMS #FTIR #Gas #Analysers #Shipping #Marine #Carbon #Capture

Read More3rd October 2025 - Pioneering Carbon Capture Projects Ready For Construction

500 new skilled clean energy jobs will be created in North Wales and the North West as two pioneering carbon capture projects move into construction. The UK’s first carbon capture-enabled cement plant at Padeswood and one of the world's first full-scale carbon capture waste-to-energy plants in Ellesmere Port, have now signed final government contracts to begin building. Together, these projects will open up highly skilled roles for engineers, construction workers, technicians, and health and safety specialists.

Cement and waste-to-energy are among the most carbon-intensive industries, with no pathway to decarbonisation without carbon capture. As the UK drives towards net zero, the Padeswood and Protos plants will deploy cutting-edge technologies capable of removing 1.2 million tonnes of CO2 each year, delivering cleaner growth while securing long-term, high-quality jobs in the cement and waste-to-energy sectors.

These flagship projects will also act as springboards for exporting British carbon capture expertise, boosting global demand for UK innovation and creating fresh economic opportunities for homegrown companies in the green economy. They are the first anchor projects to connect into Eni’s Liverpool Bay Transportation & Storage system, part of the HyNet carbon capture cluster, which was finally approved by the Prime Minister in April after years of delay.

In June 2025, the government reinforced its commitment with a £9.4 billion funding package in the Spending Review, ensuring carbon capture becomes a cornerstone of the UK’s Industrial Strategy, revitalising industrial heartlands and supporting skilled jobs across the country. The recent announcement is that investment in action: shovel-ready projects, jobs secured, and growth locked in for decades across North Wales and the North West. Padeswood will capture around 800,000 CO2 emissions annually and Protos will capture 400,000, taking the total to 1.2 million a year. Find out more about the activities of Protea and CCUS at https://www.protea.ltd.uk/carbon-capture-and-storage-ccs

#Protea #Emissions #Monitoring #CEMS #FTIR #Gas #Analysers #Shipping #Marine #Carbon #Capture

Read More1st September 2025 - Methanol & Ammonia Deemed Ready As Zero-Emission Shipping Fuels

Methanol and ammonia have moved from theory to practical application as zero-emission fuels for shipping, according to a new report from the Global Maritime Forum’s Getting to Zero Coalition. The study, From Pilots to Practice: Methanol and Ammonia as Shipping Fuels, draws on insights from around 40 major industry organisations. It concludes that methanol is now ready for low-carbon operation, while ammonia has reached the piloting stage.

The report highlights rapid progress in developing both fuels but warns that technological readiness alone will not deliver the transition at the required pace. Strong policy signals from the International Maritime Organisation (IMO) and national governments remain critical to accelerate adoption.

While not yet widely deployed, methanol and ammonia are expected to play a central role in the sector’s decarbonisation. Because they cannot be seamlessly integrated into existing shipping infrastructure, their uptake requires coordinated investment in new technologies both onshore and at sea. Demonstration projects and pilot programs are therefore essential steps toward establishing reliable supply chains.

Methanol, in particular, has advanced beyond proof of concept and is scaling up: about 60 methanol-capable vessels are currently in service, with more than 300 additional ships on order and nearly 20 ports already offering green methanol bunkering. Still, the report cautions that both fuels must achieve full maturity by around 2030 to meet the industry’s climate goals. Building robust supply chains is the key challenge, expanding the production of green methanol molecules and establishing safe, commercial ammonia bunkering at major ports.

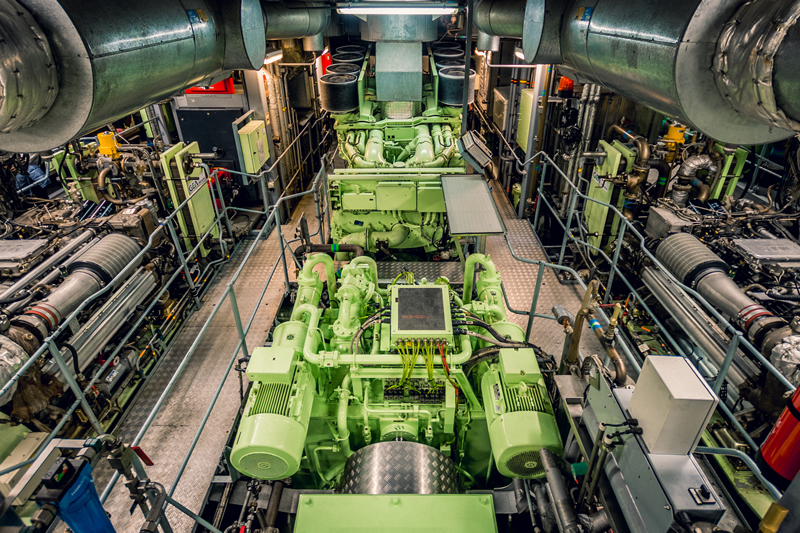

When used as marine fuel, methanol combustion produces carbon dioxide (CO2), water, and energy, along with lower levels of nitrogen oxides (NOX), sulfur oxides (SOX), particulates, and trace formaldehyde compared to heavy fuel oil. The emissions profile depends on several factors:

- Fuel Source: Green methanol, produced from renewable biomass, can achieve a net-zero lifecycle carbon footprint despite releasing CO2 during combustion.

- Combustion Conditions: Engine load, operating temperature, and the use of pilot fuels can influence emissions of NOX, methane (CH4), and nitrous oxide (N2O).

- Engine Technology: New designs are being developed to optimise combustion and further reduce pollutant output.

Protea have a range of technologies working within the marine and shipping sectors. More information can be found at https://www.protea.ltd.uk/marine.

?#Protea #Emissions #Monitoring #CEMS #FTIR #Gas #Analysers #Shipping #Marine #Carbon #Capture

Read More13th August 2025 - Carbon Capture Storage Reaching A Turning Point In Decarbonisation

Carbon capture and storage (CCS) is emerging as a critical tool in the global push toward net-zero emissions—particularly for hard-to-abate sectors such as cement, steel, and chemical manufacturing, where alternative decarbonisation options are limited. While CCS has struggled to scale in the past, new momentum suggests that is changing.

DNV’s Energy Transition Outlook: CCS to 2050 forecasts that global CCS capacity will quadruple by 2030, supported by advances in technology and a surge of industry activity. This projection is reinforced by real-world developments: in May, Northern Lights—the world’s first open-access CO2 transport and storage network in Western Norway, received its inaugural shipment of liquefied CO2 from Heidelberg Materials. In the U.S., 1PointFive’s STRATOS facility in Texas is nearing operation as the world’s largest direct air capture (DAC) plant.

Over the next five years, cumulative CCS investments are expected to total around $80 billion, with roughly two-thirds of new capacity located in North America and Europe. Policy support is set to play a pivotal role, driving cost reductions of about 14% by 2030 through lower capital expenses for capture systems and reduced transportation and storage costs.

CCS is especially important for industries where emissions are structurally embedded in the production process:

-

Cement production - Releases CO2 both from the chemical reaction in clinker production and from high-temperature heating, typically fueled by fossil energy.

-

Steel production - Relies on carbon-intensive, high-heat processes often powered by coal or gas.

-

Chemical and petrochemical production - Uses fossil feedstocks and energy, generating substantial CO2 emissions.

-

Energy generation - The burning of coal, oil, or natural gas for power and heat remains a major global source of emissions.

-

Other heavy industries - Aluminum production, refining, and certain food and beverage processes also have significant carbon footprints.

These sectors are essential to modern society, yet their emissions are difficult to eliminate without CCS. With accelerating investment, policy momentum, and breakthrough projects now underway, CCS is positioned to play a central role in cutting global carbon emissions in the decade ahead.

Closer to home in the UK we have the very large The Acorn Project which is an ambitious carbon capture, utilisation, and storage (CCUS) development in northeast Scotland. It leverages existing oil and gas infrastructure to move captured CO2 from industrial emitters to secure geological storage sites deep beneath the North Sea. Serving as the transport and storage backbone of the wider Scottish Cluster, it plays a pivotal role in the UK’s path to net zero. Critics argue that the project risks prolonging the use of fossil fuels by enabling continued oil and gas extraction in the North Sea, hindering the transition to renewable energy.

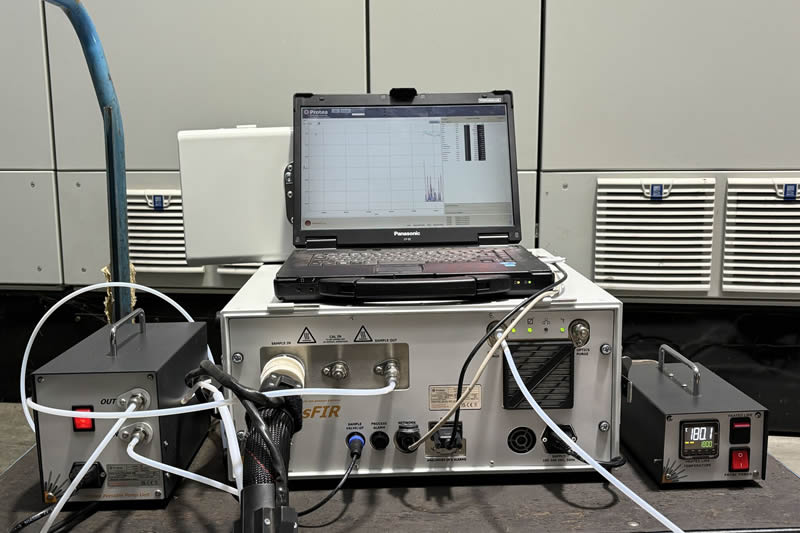

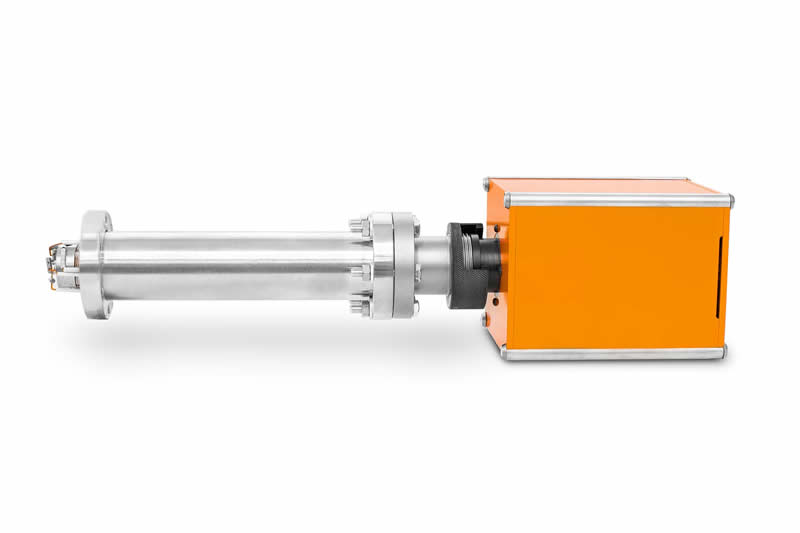

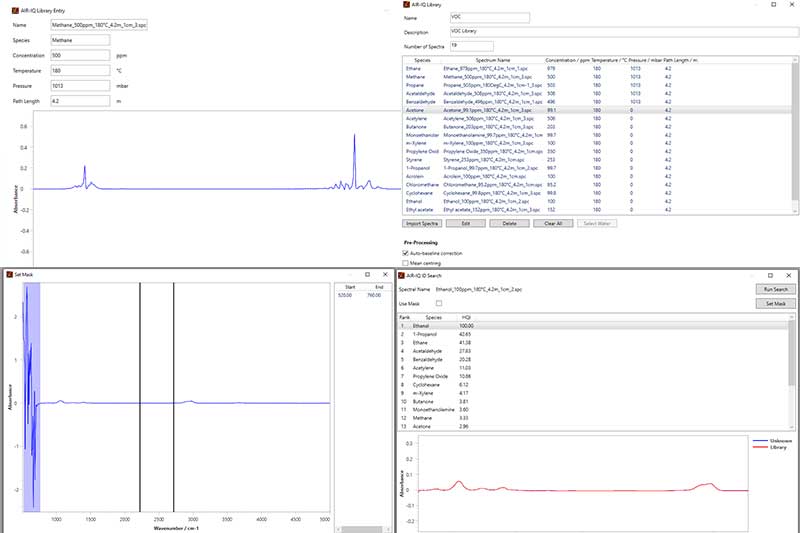

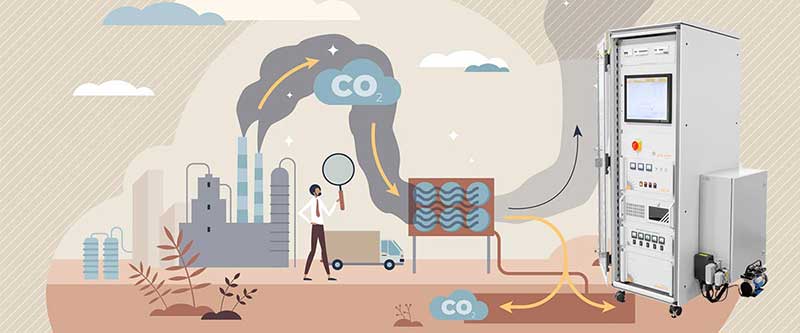

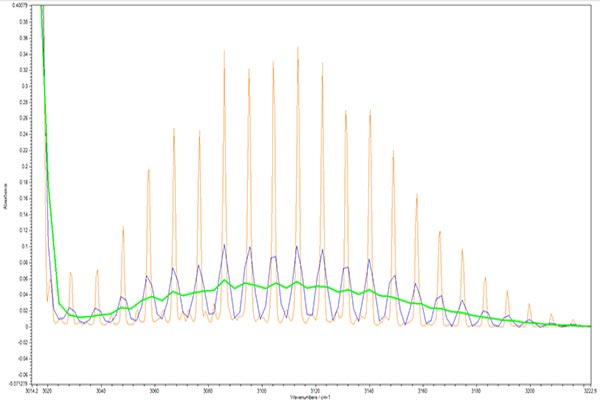

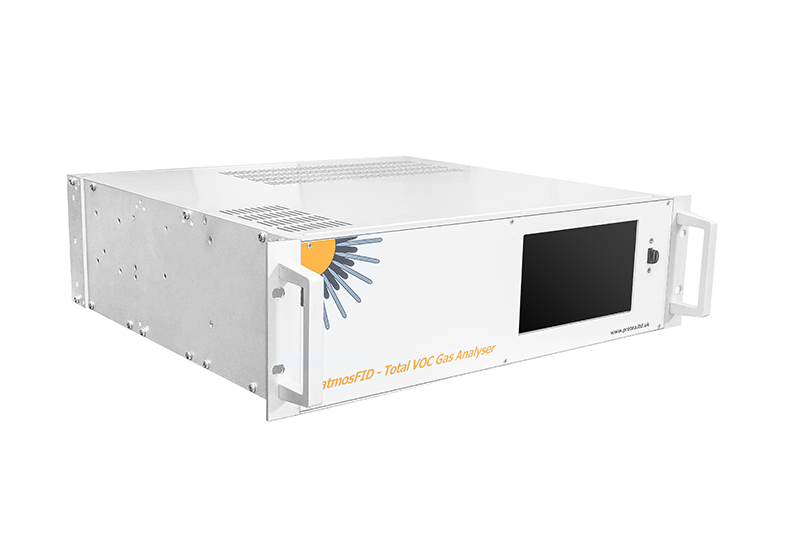

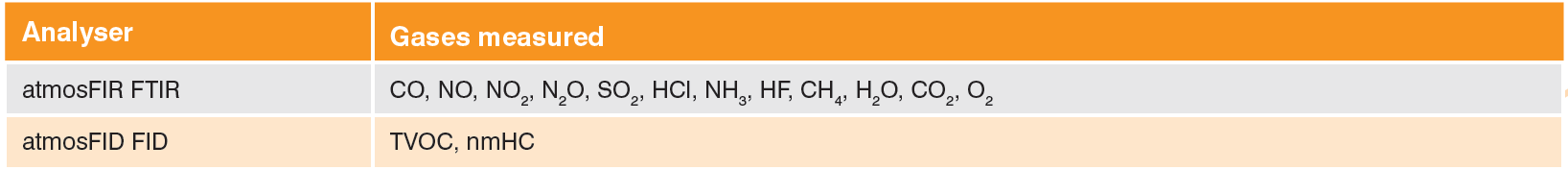

Carbon Capture and Storage (CCS) could be key in the reduction in Carbon Dioxide (CO2) from industrial processes. Protea’s range of gas analysers have been used both in research into emerging technologies for CCS, but will also play an important role in the regulatory emissions monitoring from installations of CCS. Protea’s multi-gas FTIR technology is ideally suited to new processes involving carbon reduction, such as Carbon Capture and Storage (CCS).

#Protea #Emissions #Monitoring #CEMS #FTIR #Gas #Analysers #Shipping #Marine #Carbon #Capture

Read More29th July 2025 - CCS To Capture 15% Of Shipboard Carbon Emissions By 2050

Industrial carbon capture and storage (CCS) is set to surge with forecasts of a fourfold increase in capacity by 2030 backed by $80 billion in investment. The momentum is expected to continue through 2050 with the shipping industry playing a growing role.

DNV's first global forecast on the future of carbon capture and storage (CCS) predicts that onboard CCS technology will capture 15% of ship-based carbon emissions by 2050. The report marks a shift in perception, stating that CCS is no longer a niche or theoretical solution but is poised for substantial growth, especially within the maritime industry. According to DNV, deployment of shipboard CCS systems is expected to begin scaling up around 2040.

While CCS has long been considered a potential tool for decarbonization, it is now gaining traction in regions with regulatory support (such as Europe) and in sectors where it is most practical, like power generation and oil and gas. Government subsidies are accelerating deployment: Denmark is backing the Greensand and Bifrost projects, while Norway is covering 80% of the costs for the Longship CCS initiative. In the U.S., tax incentives from the Inflation Reduction Act have sparked a surge in new CCS developments.

CCS can also be implemented onboard ships, although there are challenges. Captured CO2 must be stored in pressurised tanks that take up valuable space, and offloading infrastructure is currently limited to a few ports. Additionally, the capture process itself consumes energy, slightly raising overall fuel use. However, it offers a notable benefit: compatibility with conventional marine fuels, including heavy fuel oil (HFO), when used with scrubbers.

DNV projects that onboard CCS could capture and store 15% of maritime CO2 emissions by 2050, with the maritime sector contributing 9% of the total carbon stored via CCS worldwide. Shipping will also be instrumental in supporting offshore CCS infrastructure, especially in regions like the North Sea and Mediterranean. DNV expects ships to play a central role in transporting CO2 from coastal terminals to offshore injection sites.

As a leading classification society and maritime advisory firm, DNV continues to help shape the industry’s response to climate challenges, focusing on safety, energy efficiency, and environmental performance across the global shipping and offshore sectors.

Shipping will also have a part to play in developing offshore subsea injection and storage facilities. "Ship transport, especially in the North Sea or the Mediterranean Sea, will likely play a key role in transporting CO2 between shore terminals or via offshore injection," DNV predicted. DNV, formerly known as Det norske Veritas, is a leading international certification body and risk management company with a significant presence in the maritime industry. They provide a range of services including classification, advisory, and software solutions for the global shipping and offshore sectors. DNV's core focus is on enhancing safety, quality, energy efficiency, and environmental performance within the maritime world.

Carbon Capture and Storage (CCS) could be key in the reduction in Carbon Dioxide (CO2) from industrial processes. Protea’s range of gas analysers have been used both in research into emerging technologies for CCS, but will also play an important role in the regulatory emissions monitoring from installations of CCS. Protea’s multi-gas FTIR technology is ideally suited to new processes involving carbon reduction, such as Carbon Capture and Storage (CCS). For more information visit https://www.protea.ltd.uk/carbon-capture-and-storage-ccs/.

#Protea #Emissions #Monitoring #CEMS #FTIR #Gas #Analysers #Shipping #Marine #Carbon #Capture

Read More21st July 2025 - Global Shipping Industry Struggles To Navigate Net Zero Transition

The shipping sector, responsible for 3% of global emissions, is under growing pressure to decarbonise. Upcoming International Maritime Organization (IMO) rules require shipowners to cut emissions by 65% by 2040. The EU has already extended its emissions trading scheme to shipping and introduced FuelEU Maritime, setting lifecycle GHG intensity limits.

Despite growing regulatory momentum, the path to net zero remains complex. A wide range of technologies and fuels are being explored:

- Ammonia: Fortescue's Green Pioneer is trialing ammonia as a marine fuel, but safety, infrastructure, and supply issues persist. Only 25 ammonia-capable ships are on order globally.

- Methanol: Maersk leads with dual-fuel vessels using green and e-methanol. It now operates 13 methanol-capable ships and has ordered 20 more. European and U.S. producers are scaling e-methanol production, though costs remain high.

- Biofuels: Demand is growing due to ease of adoption, but sustainability concerns loom. NGOs warn that by 2030, most marine biofuels may come from palm and soy oil, which could increase overall emissions.

- Wind-Assisted Propulsion: Technologies like rotor sails and suction wings are gaining traction. Around 50 ships use wind-assisted systems today, with 97 more on order. These can deliver fuel savings of 20%-40%.

- Operational Efficiency: Immediate gains are available through weather routing, slow steaming, and hull cleaning. Tech firms like Sofar Ocean are using real-time data to optimise voyages and cut emissions.

The Getting to Zero Coalition (a group of 200 maritime stakeholders) argues the sector must use scalable zero-emission fuels to meet 2050 targets. However, uncertainty around fuel availability, infrastructure, and regulation continues to delay investment. While some criticise the IMO’s plan as lacking ambition, industry leaders say it offers a critical signal to drive forward decarbonisation. “You can continue to pollute,” said Fortescue’s Sara Edmonson, “but delaying transition will be costly.”

According to a recent article by the Financial Times, global ocean temperatures in May 2025 reached their second-highest level on record, highlighting a concerning two-year trend of rapid marine warming. The data, sourced from the EU’s Copernicus Climate Change Service, shows the average sea surface temperature for the month was 20.79°C, just 0.14°C below the record set in May 2024.

At the same time, atmospheric CO2 levels continued to climb. Global concentrations peaked at an average of 426 parts per million (ppm) in March, up from 423ppm the previous year. For context, CO2 levels have surged from around 300ppm over the past six decades. This trend raises growing concerns about the oceans' capacity to absorb carbon dioxide and regulate the planet’s climate.

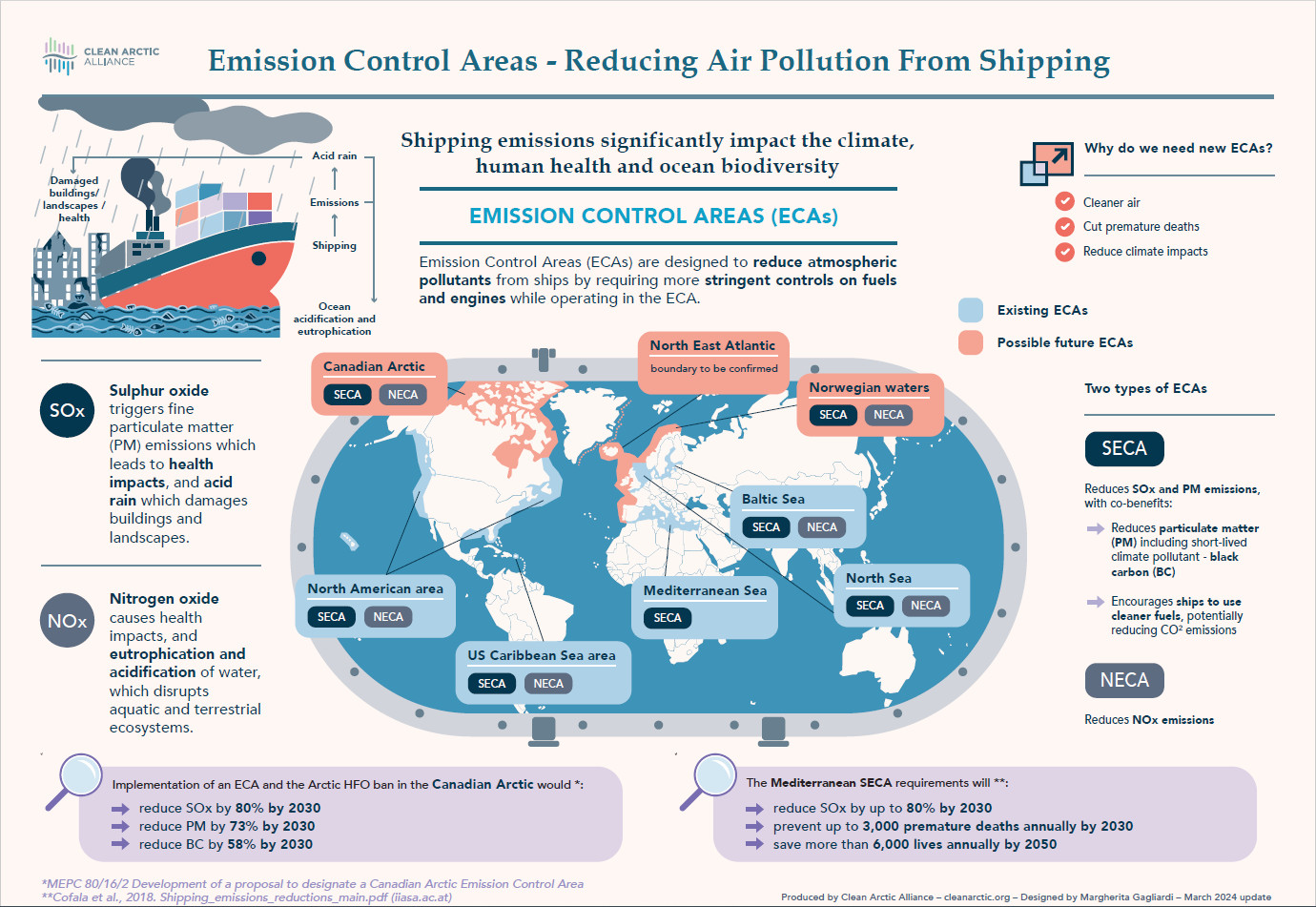

The most important gases in terms of emissions are currently sulphur oxides (SOx) and nitrogen oxides (NOx). The creation of Emission Control Areas and stringent limits on fuel sulphur content in port are challenging particularly for the shipping industry and its suppliers. Ship operators have near imminent decisions to make based on a complex set of circumstances and a fluid regulatory background. Find out more at https://www.protea.ltd.uk/marine/.

#Protea #Emissions #Monitoring #CEMS #FTIR #Gas #Analysers #Shipping #Marine #Carbon #Capture

Read More14th July 2025 - Carbon Capture Surges as Economics Policy & Industry Demand Align

After years of skepticism and stalled progress, carbon capture and storage (CCS) is experiencing a dramatic resurgence. Once criticized as too costly, unreliable, or a lifeline for fossil fuels, CCS is now expanding rapidly—driven by technological improvements, strong policy support, and rising demand from sectors like AI and data centers.

"The pace of interest and investment has snowballed,” said Jessie Stolark, executive director of the Carbon Capture Coalition. “Companies with hard-to-abate emissions are increasingly seeing CCS as a necessary tool in their decarbonization strategy."

A Shift in Momentum

CCS works by capturing CO2 emissions from industrial facilities, such as coal plants, steel mills, and cement factories, compressing the gas, and injecting it deep underground for long-term storage. While the concept is straightforward, early efforts in the 2010s faced significant setbacks due to high costs and technical challenges.

That changed when economic incentives aligned. The U.S. federal tax credit for CCS, known as 45Q, was enhanced in 2018 and expanded further under the Inflation Reduction Act in 2022. These incentives sparked a surge in development: the number of global CCS projects grew from 392 in 2023 to 628 in 2024. The U.S. now leads the world in active and planned CCS initiatives, outpacing the next four countries, Canada, the U.K., Norway and China combined.

Europe’s Big Bet

In Europe, CCS is now a core pillar of long-term climate strategy. Industrial emissions account for roughly 25% of the EU’s total, and reaching climate neutrality by 2050 will require drastic reductions, many of which can only be achieved through CCS.

To meet this challenge, the European Commission has launched an Industrial Carbon Management Strategy. Its targets are ambitious: 50 million tons of CO2 storage capacity by 2030, scaling up to 280 million tons by 2040 and 450 million tons by 2050, equivalent to about 13% of the EU's current emissions.

Achieving this will require sweeping infrastructure investments. Capture systems must be installed on power plants, cement kilns, hydrogen and chemical facilities, and waste incinerators. These sources will need to connect to an estimated 19,000 kilometers of CO2 pipelines across Europe. Temporary storage hubs will be built at ports, supported by a new fleet of CO2 transport ships. Meanwhile, depleted oil and gas reservoirs, at least 800 meters underground, must be surveyed and converted for permanent storage.

A Tool, Not a Silver Bullet

Despite the momentum, CCS remains controversial in some circles. Critics argue that it risks prolonging fossil fuel dependency and diverting attention from renewable solutions. Yet the technology's rapid adoption suggests it’s becoming a key part of the global decarbonisation toolkit, particularly for sectors where emissions are difficult or impossible to eliminate entirely.

In a world racing toward net-zero targets, CCS is no longer just a backup plan. It’s becoming a strategic necessity. Estimates vary, but a recent assessment puts the number of operational coal-fired power plants in the European Union at around 256. This figure remains fluid, as some facilities are being phased out while others may be temporarily reactivated in response to changing energy market conditions.

The largest power station in the UK is Drax Power Station, located in North Yorkshire. It's also the biggest renewable power station in the UK, generating enough electricity for 4 million homes. While historically a coal-fired plant, Drax has transitioned to using sustainable biomass, primarily wood pellets, as its main fuel source. Drax Power Station is the UK's largest single source of CO2 emissions, primarily from burning wood pellets for electricity generation. In 2023, it emitted 11.5 million tonnes of CO2, accounting for 2.9% of the UK's total territorial emissions.

Carbon Capture and Storage (CCS) could be key in the reduction in Carbon Dioxide (CO2) from industrial processes. Protea’s range of gas analysers have been used both in research into emerging technologies for CCS, but will also play an important role in the regulatory emissions monitoring from installations of CCS. Find out more about our CCS systems at https://www.protea.ltd.uk/carbon-capture-and-storage-ccs/.

#Protea #Emissions #Monitoring #CEMS #FTIR #Gas #Analysers #Shipping #Marine #Carbon #Capture

Read More7th July 2025 - GHG Emissions At Ports On The Rise Despite Initiatives

A new study has revealed that greenhouse gas (GHG) emissions at major global ports are still rising, despite advances in technology and sustainability initiatives. The report, titled “Quantifying Port Carbon Footprints: Container Vessel Emissions Analysis in Major Global Terminals,” analyses emissions from container shipping operations at key ports in Europe, North America, and Asia. It shows that factors like port congestion and operational inefficiencies significantly affect emissions levels.

Among the findings, Shanghai port topped the emissions list with 140,000 tons, more than Singapore, even though it handled fewer vessels. This highlights that emissions are not solely tied to vessel numbers. U.S. ports experienced particularly high emissions and congestion in early 2025, due to a surge in shipping volumes ahead of new tariffs. Meanwhile, Singapore demonstrated that innovations like Digital Twin technology can help reduce emissions even under heavy traffic.

Additionally, ports around the world are adopting initiatives to reduce their emissions. For instance, earlier this month, the Port of Rotterdam Authority launched Carbonbid, a new sustainability initiative aimed at supporting companies in the port area to reduce greenhouse gas emissions. The report emphasises that elements such as port layout, terminal capacity, vessel dwell times, and idle engine use are major emission drivers. Furthermore, the study underscores the need for smarter, more efficient port operations to reduce environmental impact.

The VesselBot report also finds that port congestion and operational inefficiencies have a substantial impact on greenhouse gas (GHG) emissions. U.S. ports recorded the highest congestion levels in January and February 2025, alongside record-breaking container volumes and related emissions. This surge was largely attributed to preemptive shipping in anticipation of new tariffs.

The report underscores the complex relationship between port activity and emissions, While an increase in vessel traffic typically results in higher emissions, our data shows that operational performance and efficiency are critical factors in managing environmental impact. The study uses a combination of vessel geospatial tracking, operational data, and cargo volume metrics to calculate container vessel GHG emissions. It also highlights how port design, terminal capacity, vessel dwell times, and engine use during idling periods significantly affect emission levels, offering a more nuanced view than simply counting vessel movements.

The need to demonstrate environmental responsibility is key for today’s marine and offshore industries. For more information on our Marine Emissions systems please visit https://www.protea.ltd.uk/marine

#Protea #Emissions #Monitoring #CEMS #FTIR #Gas #Analysers #Shipping #Marine #Carbon #Capture

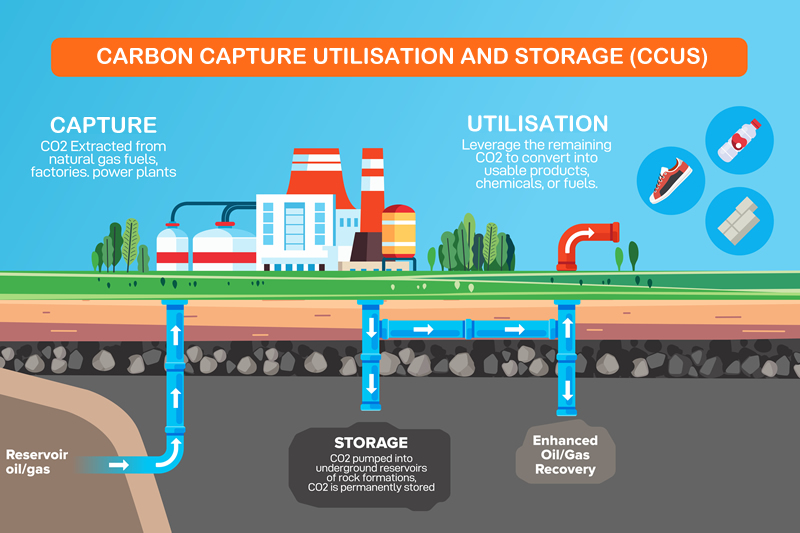

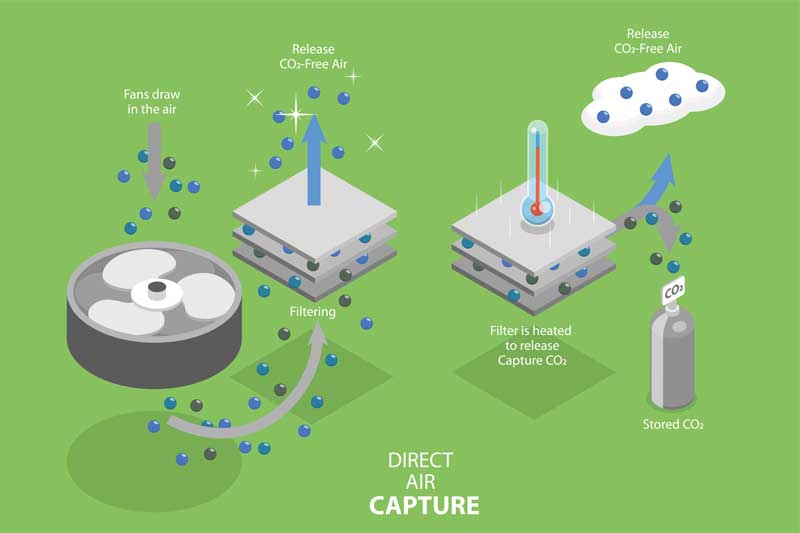

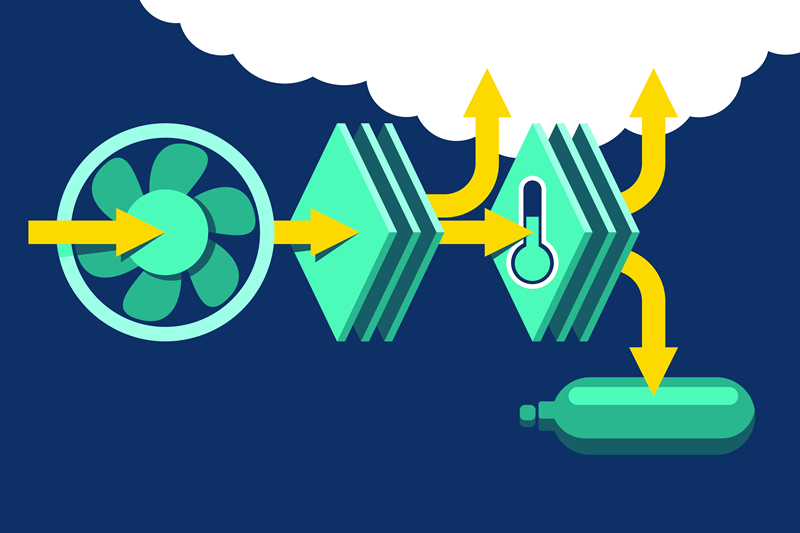

Read More30th June 2025 - Carbon Capture Utilisation & Storage In A Nutshell

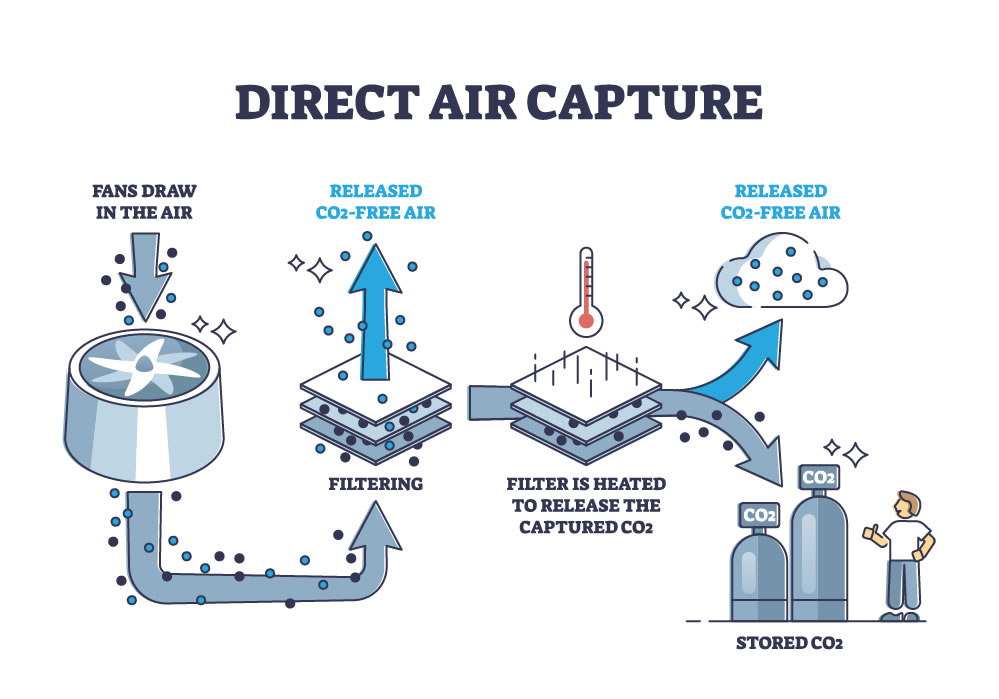

CCUS is a climate technology that captures carbon dioxide (CO2) emissions from industrial processes and power generation, then either uses it in other applications or stores it permanently underground to prevent it from entering the atmosphere

What is CCUS and Why Does it Matter?

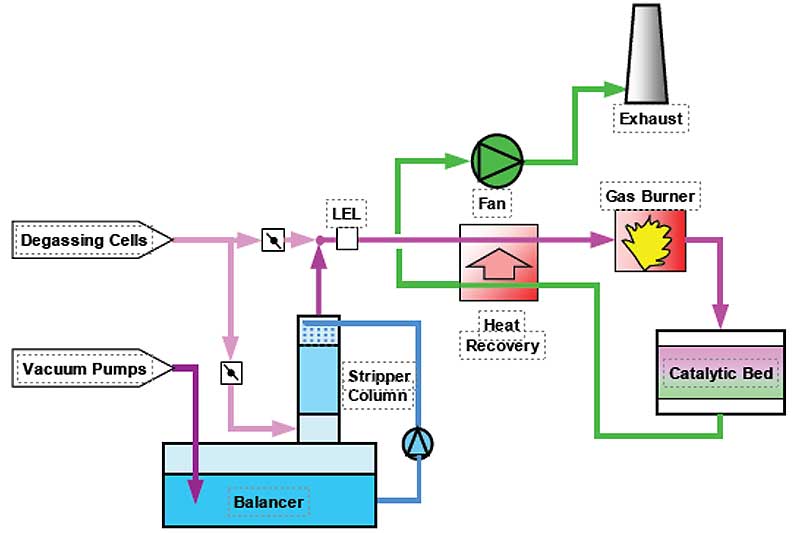

Carbon Capture, Utilisation, and Storage (CCUS) is a vital technology for reducing emissions from heavy industry and supporting low-carbon power generation. It captures carbon dioxide (CO2) emissions at their source, compresses them, and transports the CO2 by pipeline or ship for either reuse or safe, long-term storage deep underground. CCUS is essential for cutting emissions from heavy industries. It also supports low-carbon power from gas and enables hydrogen energy especially important when renewable sources like wind or solar aren't available.

How Does CCUS Work?

CCUS captures CO2 from industrial facilities or power plants and prevents it from entering the atmosphere. The CO2 is stored in porous rock formations, such as depleted oil and gas fields or deep saline aquifers, beneath layers of impermeable rock (called caprock), which trap the gas securely. Storage sites are continuously monitored to ensure safety and permanence.

Is CCUS Proven and Safe?

Yes, CCUS has been safely in operation since 1996 at Norway's Sleipner site in the North Sea. This experience paved the way for larger projects like Northern Lights, which now offers commercial CO2 storage for European industries. All components of the CCUS chain have been used globally for decades. In the UK, existing Health and Safety regulations, combined with offshore industry expertise, make CCUS a safe and manageable solution.

Can CCUS Help Fight Climate Change?

CCUS is the lowest-cost route to net zero. It's not just an option, it's a necessity. It allows us to cut emissions from sectors that can't otherwise be decarbonised and plays a critical role in reaching our climate goals.

Why Do We Still Need CCUS if Renewables Are Growing?

To keep the lights on in all conditions, we need low-carbon power that works 24/7. CCUS-equipped gas power stations provide this reliability. Beyond electricity, CCUS is also key to decarbonising industries like cement and steel, which have few other viable options.

What About the Cost of CCUS?

Costs vary depending on where CO2 is captured, how it's transported, and where it's stored. But compared to other decarbonisation options, CCUS is often the most practical, or the only, solution currently available.

Is There Enough Space to Store Captured Carbon?

The UK's North Sea could store up to 78 gigatonnes of CO2, enough to hold centuries of emissions. We believe the UK has a strong case to become a global carbon storage hub. CCUS is a safe, proven, and essential technology for cutting emissions in hard-to-abate sectors, ensuring reliable low-carbon power, and helping the world reach net-zero targets, at a cost that is often competitive and with ample storage capacity available.

#Protea #Emissions #Monitoring #CEMS #FTIR #Gas #Analysers #Shipping #Marine #Carbon #Capture

Read More23rd June 2025 - Carbon Capture Reducing Maritime Shipping Emissions

Maritime shipping is responsible for around 3% of global greenhouse gas emissions, making decarbonisation of the sector essential to achieving international climate goals. Industry leaders have recognised the urgency, committing to net-zero emissions by 2050, but reaching that target will require overcoming significant challenges.

As one of the most difficult sectors to decarbonise, shipping will need a multi-faceted transformation. That includes stronger policy frameworks, real-time emissions monitoring, the adoption of breakthrough technologies like hydrogen fuel cells, and more efficient logistics and routing. Encouragingly, progress is being made on all fronts.

In a major development, the International Maritime Organization (IMO) recently adopted a Net-Zero Framework, a landmark move that introduces mandatory emissions caps and carbon pricing across the global maritime sector. Set to be formally adopted in October 2025 and enforced beginning in 2027, the regulations will apply to vessels over 5,000 gross tons, which account for 85% of international shipping’s CO2 output.

While the framework marks a major step forward for climate action, it also presents potential economic pressures for operators, particularly if implementation is uneven or delayed. However, a promising innovation from Scandinavia may offer a lifeline: a new technology that could allow existing, carbon-intensive fleets to drastically reduce emissions without the need for complete vessel replacement. This kind of innovation could help balance environmental responsibility with economic practicality, paving the way for a cleaner, more resilient global shipping industry.

Wärtsilä has officially launched its carbon capture solution (CCS) to the global maritime market, marking a major milestone in the industry's decarbonisation efforts. The system has demonstrated the ability to cut vessel CO2 emissions by up to 70%, offering shipowners a practical and immediate tool to comply with tightening environmental regulations.

The announcement follows the successful installation of the world’s first full-scale CCS system aboard Solvang ASA’s Clipper Eris. The technology captures emissions from all onboard exhaust gas sources, and has been operating since the vessel departed Singapore in February 2025.

Installed on the 21,000 m2 ethylene carrier for live testing and optimisation, the system supports Solvang ASA’s commitment to low-carbon shipping while advancing the industry’s progress toward the IMO’s 2050 greenhouse gas reduction goals. Wärtsilä’s breakthrough offers a scalable solution for existing fleets, potentially transforming the way the industry addresses shipboard emissions in the near term.

#Protea #Emissions #Monitoring #CEMS #FTIR #Gas #Analysers #Shipping #Marine #Carbon #Capture

Read More16th June 2025 - UK Approves Viking CCS Pipeline to Support Major Carbon Capture Efforts

The UK government has granted formal approval for the Viking onshore pipeline, a £200 million (~$250 million) project that will play a central role in large-scale carbon capture and storage (CCS) initiatives off the coast of Lincolnshire.

The 34-mile underground pipeline will carry dense-phase CO2 from Immingham to the Theddlethorpe Gas Terminal, where it will then be transported offshore for permanent storage in the Viking gas fields beneath the North Sea. Led by Harbour Energy and supported by BP, the Viking CCS pipeline is a core element of a wider CCS strategy expected to attract £7 billion (~$9 billion) in investment to the Humber region by 2035. The project is forecast to deliver strong economic benefits, including:

- Creation of up to 10,000 construction-related jobs

- A projected £4 billion (~$5.2 billion) boost to the UK economy over the next decade

The development plan includes extensive infrastructure such as valve stations, inspection and venting systems, construction compounds, material storage facilities, and access roads. Approval followed a comprehensive six-month review by the Planning Inspectorate, which included input from local communities, councils, and statutory bodies. Based on its findings, the Inspectorate recommended approval, and final consent was granted by the Secretary of State for Energy Security and Net Zero.

The Viking fields are estimated to offer 300 million metric tons of COCO2 storage capacity, with the goal of reaching an annual injection rate of 10 million tons by 2030. Key Elements of a CCS Pipeline:

Purpose:

- To move CO2 in a safe, efficient, and sealed manner from the point of capture to the point of storage.

- It plays a critical role in the CCS chain, which includes:

- Capture of CO2 at source

- Transport (via pipeline, ship, or truck)

- Storage, usually in depleted oil/gas reservoirs or deep saline aquifers

Transport Method:

- CO2 is usually transported in a dense or supercritical phase, which means it's compressed into a fluid-like state to maximise efficiency and minimise pipeline size.

- CCS pipelines are similar in design to oil or gas pipelines but are specifically engineered to handle CO2's physical properties and prevent leaks.

- They include monitoring systems, valves, and safety features to manage pressure, temperature, and flow.

End Destination:

- The pipeline leads to permanent geological storage, often thousands of meters underground, where the CO2 is injected into porous rock formations capped by impermeable layers that prevent its release.

#Protea #Emissions #Monitoring #CEMS #FTIR #Gas #Analysers #Shipping #Marine #Carbon #Capture

Read More11th June 2025 - Protea Sales Team & Alantra Panel Discuss Marine Decarbonisation

The Protea sales team recently visited Alantra, joining a panel discussing decarbonisation in the marine industry. The maritime industry is the backbone of global trade, but it faces a critical challenge, decarbonising while maintaining its vital role in enabling the flow of goods worldwide. Alantra have created a "Maritime Decarbonisation Leaders Report" which explores the transformative efforts underway in the shipping sector to address climate change.

With the industry currently reliant on oil-based fuels for 99% of its energy needs, rapid decarbonisation has become a priority for policymakers, customers, and industry leaders alike. This report delves into the challenges and opportunities in transitioning to cleaner technologies, featuring:

- An overview of the current state of maritime decarbonisation and the sector’s progress toward emissions reduction targets

- Key challenges, including the future of maritime fuels, investment needs, and infrastructure gaps for greener shipping

- Profiles of a dozen innovative maritime businesses leading the way in decarbonisation efforts

Alantra’s maritime and offshore team combines financial, technical, and commercial expertise to present these insights, offering a comprehensive view of the industry’s journey toward sustainability. As a trusted advisor in the maritime sector, Alantra is committed to supporting clients in navigating these challenges and achieving their sustainability goals.

#Protea #Emissions #Monitoring #CEMS #FTIR #Gas #Analysers #Shipping #Marine #Carbon #Capture #Alantra

Read More9th June 2025 - Shipping Charts Course To Net Zero Under New IMO Climate Framework

The International Maritime Organisation (IMO) has taken a landmark step toward decarbonising global shipping, approving the first-ever regulatory framework targeting net-zero greenhouse gas emissions by around 2050. The decision, made during the IMO’s Marine Environment Protection Committee (MEPC 83) session in April 2025, sets the stage for transformative changes across the maritime sector.

At the core of the new framework is a mandatory reduction in the carbon intensity of marine fuels, assessed on a 'well-to-wake' basis, accounting for emissions from fuel production through to combustion. The rules apply to large vessels over 5,000 gross tons, which are responsible for the bulk of international shipping emissions. A central feature of the framework is a global emissions pricing mechanism. Vessels that exceed emissions thresholds will be required to purchase remedial units, while those using low- or zero-emission technologies may receive credits or financial incentives. Though the pricing structure is still being finalised, the IMO has made clear that carbon will come at a cost for the maritime industry.

Formal adoption of the regulations is expected in October 2025, with enforcement scheduled to begin in 2027. To support implementation and ensure a just transition, the IMO has also unveiled plans for a Global Net-Zero Transition Fund. Funded by revenue from emissions pricing, it will provide:

- Incentives for cleaner vessels

- Investment in green infrastructure and innovation

- Training and capacity-building, particularly in developing countries

The fund is specifically designed to help vulnerable regions, such as small island developing states and least developed countries, mitigate economic risks associated with the transition and maintain access to global trade. As momentum builds around climate action, the IMO’s decision marks a decisive shift: international shipping is moving beyond voluntary measures toward binding climate accountability. While final details will be refined in the coming months, the direction is clear, the era of unregulated maritime emissions is nearing its end.

- Approval of the IMO Net-Zero Framework (Mid-Term GHG Measures)

- MEPC 83 approved draft amendments to MARPOL Annex VI, introducing a new Chapter 5 that establishes the "IMO Net-Zero Framework."

- This framework includes:

- A technical element: a goal-based marine fuel standard designed to gradually lower the greenhouse gas (GHG) intensity of marine fuels.

- An economic element: a pricing mechanism for maritime GHG emissions.

- These measures are scheduled for formal adoption at an extraordinary MEPC session in October 2025 and are expected to enter into force on 1 March 2027.

- Review of Short-Term GHG Reduction Measures

- MEPC 83 completed Phase 1 of the review of short-term GHG measures, which include the Energy Efficiency Existing Ship Index (EEXI), the Ship Energy Efficiency Management Plan (SEEMP), and the Carbon Intensity Indicator (CII) rating scheme.

- Key actions taken:

- Adoption of amendments to the 2021 Guidelines on the operational carbon intensity reduction factors (CII reduction factors) for 2027 to 2030.

- Approval of draft amendments to Regulation 27 of MARPOL Annex VI to enhance transparency by making the IMO's data collection system (IMO DCS) on ship fuel consumption more accessible.

- Agreement on a work plan for Phase 2 of the review, to run from Spring 2026 to Spring 2028, focusing on enhancing the SEEMP framework and further developing CII metrics.

- Onboard Carbon Capture and Storage (OCCS)

- MEPC 83 approved a work plan for developing a regulatory framework for the use of onboard carbon capture and storage (OCCS) technologies, with expected completion by 2028.

#Protea #Emissions #Monitoring #CEMS #FTIR #Gas #Analysers #Shipping #Marine #Carbon #Capture

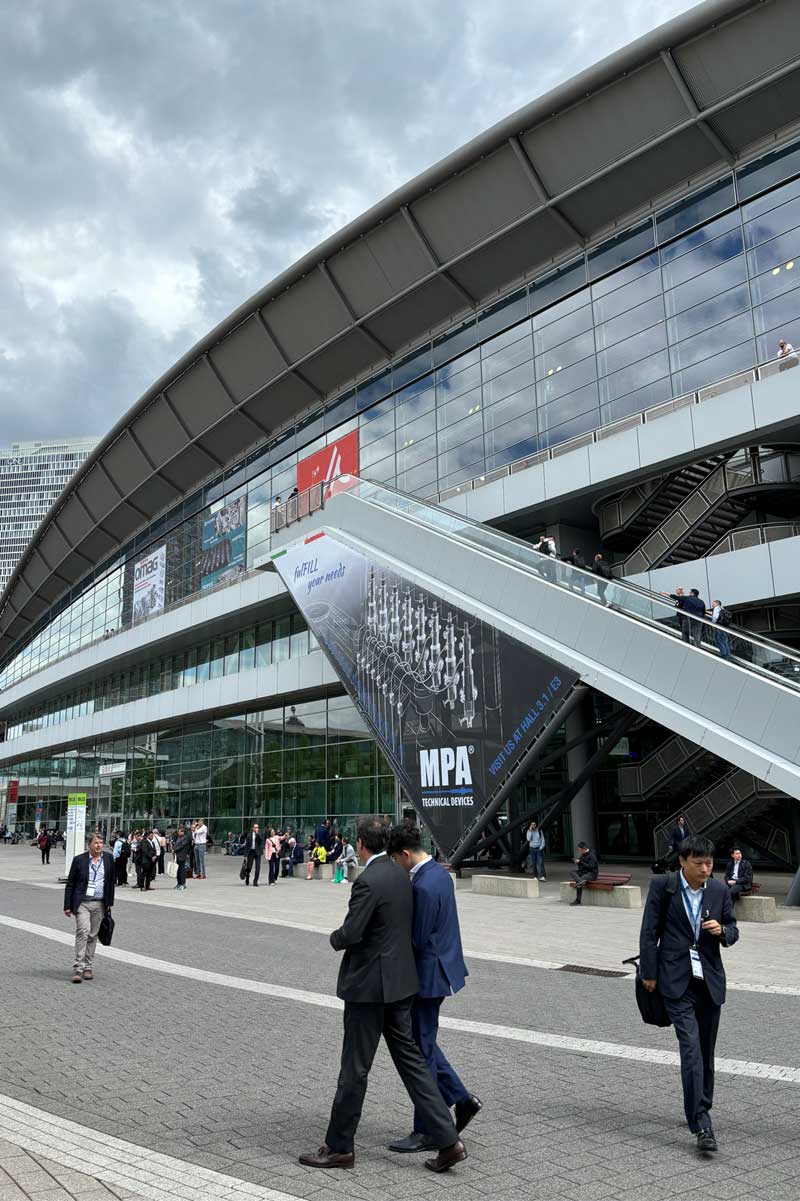

Read More3rd June 2025 - Come & Visit Protea at Nor-Shipping 2025

Protea are exhibiting at Nor-Shipping 2025 from Tuesday 3rd to Friday 6th June 2025 in Oslo, Norway. Our booth number is D06-18 in Hall D. Nor-Shipping is at the centre of the oceans. Exhibition opening hours: Tuesday 3rd June to Thursday 5th June 10.00 - 17.00. Friday 6th June 10.00 - 15.00.

Nor-Shipping is at the centre of the oceans. This is where the maritime and ocean industries meet every two years. A natural hub for key decision makers from across the world to connect, collaborate and do deals to unlock new business opportunities. This is your arena for ocean solutions. Come and visit Protea by registering for your tickets at https://nor-shipping.com/

#Protea #Emissions #Monitoring #CEMS #FTIR #Gas #Analysers #Shipping #Marine #Carbon #Capture

Read More2nd June 2025 - UK Unveils Maritime Decarbonisation Strategy For Emission Pricing & Fuel Regulations

The UK has launched a comprehensive new maritime decarbonisation strategy, building on international efforts while placing greater focus on domestic emissions and smaller vessels. Maritime Minister Mike Kane presented the strategy to the House of Commons, outlining the next phase in aligning the sector with the country’s climate goals.

In 2019, the UK’s domestic maritime sector generated approximately eight million tonnes of CO2-equivalent emissions on a full lifecycle basis. With a goal of achieving net-zero lifecycle greenhouse gas emissions by 2050, the UK has set interim targets of a 30% reduction by 2030 and 80% by 2040, relative to 2008 levels.

Key elements of the new strategy include:

- Expansion of the UK Emissions Trading Scheme to cover domestic maritime GHG emissions beginning in 2026.

- Support for global emissions pricing, with the UK advocating for the International Maritime Organization (IMO) to adopt a framework by 2027.

- Introduction of domestic fuel regulations, pending consultation in 2026, to drive the uptake of zero and net-zero GHG emission fuels and energy sources.

- Port-level initiatives to reduce emissions at berth and promote broader environmental planning.

A notable feature of the strategy is its inclusion of smaller vessels, particularly those under 400 gross tons. The government acknowledges that some sectors, such as fishing, may face challenges, while others—like offshore wind support vessels, could lead innovation. A call for evidence has been issued to guide policy development for this segment. The strategy also encourages ports to evaluate their own decarbonization efforts and consider wider environmental strategies, aligning infrastructure with national climate ambitions.

Despite acknowledging the complexity of the transition, the government sees significant economic potential. Conservative estimates suggest that decarbonizing the UK maritime sector could generate £130 to £180 million ($168 to $233 million) in gross value added annually and support 1,400 to 2,100 jobs per year through 2050. The UK Chamber of Shipping welcomed the new strategy, describing it as a timely successor to the 2019 Clean Maritime Plan and a crucial step forward for the industry. Maritime decarbonisation is critically important for both environmental and economic reasons. Here's a breakdown of why it matters:

- Global Emissions Impact

- Shipping accounts for ~3% of global greenhouse gas emissions—roughly equal to the emissions of a major industrialized country.

- Without action, maritime emissions could rise by up to 130% by 2050 due to growing trade volumes.

- Climate Goals Cannot Be Met Without It

- To achieve the Paris Agreement’s 1.5°C target, every sector—including shipping—must reduce emissions rapidly.

- Maritime transport is included in net-zero national strategies and must align with broader climate goals.

- Hard-to-Abate Sector

- Shipping is energy-intensive and difficult to electrify, making it one of the "hard-to-abate" sectors.

- Decarbonisation solutions (like alternative fuels, efficiency technologies, and carbon capture) are vital for progress.

- Regulatory Pressure is Increasing

- The International Maritime Organization (IMO) has set a target of net-zero emissions by 2050.

- Regional policies (e.g., EU ETS, UK Maritime Strategy) are introducing emission pricing, fuel mandates, and GHG intensity limits.

- Economic and Trade Implications

- Decarbonisation can create new markets and jobs (e.g., in green fuel production, retrofit technologies, port infrastructure).

- Ships that don’t comply with emerging standards risk losing market access or facing high carbon costs, impacting trade competitiveness.

- Environmental and Social Benefits

- Cleaner fuels and technologies reduce air pollution, including SOx, NOx, and particulate matter, improving health near ports and coastal areas.

- Supports sustainable development goals (SDGs) like climate action, health, and responsible consumption.

#Protea #Emissions #Monitoring #CEMS #FTIR #Gas #Analysers #Shipping #Marine #Carbon #Capture

Read More27th May 2025 - World's First Wind Powered Carbon Removal Plant Planned in Texas

A groundbreaking project in Texas could become the world’s first direct air capture (DAC) facility powered primarily by on-site wind energy. The initiative, announced by three European companies, aims to address one of the biggest challenges in carbon removal - high operating costs. By using behind-the-meter wind power electricity generated and consumed on site, the facility will avoid grid reliance and benefit from low-cost, renewable energy.

Slated to begin operations in 2028, the plant is designed to eventually remove up to 500,000 metric tons of CO2 per year, more than the annual emissions of a typical natural gas power plant, according to EPA data. This would make it the largest DAC facility announced to date, though several similarly scaled projects are under development.

The project is a collaboration between Return Carbon, a Dutch development and investment firm; Skytree, a Netherlands-based DAC technology company; and the North American renewables division of EDF, the French state-owned utility. Captured CO2 will be permanently stored underground by Verified Carbon, a Texas-based firm. “This is a new framework we've agreed upon with EDF,” said Martijn Verwoerd, co-founder and managing director of Return Carbon. “That’s why we’re announcing it now.” As scientists stress the urgent need to reduce carbon emissions, mainly from burning fossil fuels, there is growing consensus that carbon removal technologies like DAC are also essential to draw down existing CO2 already in the atmosphere.

Here is a summary of the key benefits of Carbon Capture and Storage (CCS):

- Significant Emissions Reduction

- Captures up to 90-95% of CO2 emissions from industrial sources (like power plants, steel, cement, and ships).

- Helps reduce emissions from hard-to-abate sectors where alternatives are limited.

- Supports Net-Zero Goals

- Essential for achieving net-zero emissions by 2050, especially in combination with other technologies.

- Can enable negative emissions when paired with bioenergy (BECCS).

- Enables Continued Use of Existing Infrastructure

- Allows continued use of fossil fuel assets (e.g., power plants, ships) with reduced climate impact.

- Helps manage the transition period before full decarbonisation technologies are ready.

- Industrial and Economic Benefits

- Preserves industrial competitiveness by offering a decarbonization pathway for emissions-intensive industries.

- Can create jobs in engineering, infrastructure, and CO2 transport and storage sectors.

- Enhances Blue Hydrogen Production

- CCS is critical for producing blue hydrogen (hydrogen from natural gas with captured CO2), a lower-carbon energy carrier.

- Flexible Deployment

- Can be applied to stationary sources (factories, refineries) and mobile ones (ships, in emerging technologies).

- Stored CO2 can be injected into depleted oil/gas fields or deep saline formations.

CCS is a critical tool in the climate solution portfolio, especially for cutting emissions in sectors that can’t easily switch to renewables. It’s not a silver bullet, but it's vital for buying time and achieving deep decarbonisation.

#Protea #Emissions #Monitoring #CEMS #FTIR #Gas #Analysers #Shipping #Marine #Carbon #Capture

Read More21st May 2025 - Protea Exhibiting at Nor-Shipping 2025

Protea will be exhibiting at Nor-Shipping 2025 held in June this year. Dates of the event are Monday 2nd to Friday 6th June 2025 in Oslo, Norway (Trade show opens Tuesday 3rd). Our booth number is D06-18 in Hall D. Nor-Shipping is at the centre of the oceans. This is where the maritime and ocean industries meet every two years. A natural hub for key decision makers from across the world to connect, collaborate and do deals to unlock new business opportunities. This is your arena for ocean solutions. Come and visit Protea by registering for your tickets at https://nor-shipping.com/

Nor-Shipping has been since 1965 an activity-filled arena attracting key maritime industry players from across the world. The presence of leading heads from the entire maritime value chain and press, makes Nor-Shipping one of the world’s most recognized meeting places for strategic deal making and networking. Many of the best business relationships begin outside traditional meeting rooms. Nor-Shipping provides an unbeatable arena for professional networking and socialising.

Exhibition opening hours: Tuesday 3rd June to Thursday 5th June 10.00 - 17.00. Friday 6th June 10.00 - 15.00.

#Protea #Emissions #Monitoring #CEMS #FTIR #Gas #Analysers #Shipping #Marine #Carbon #Capture #NorShipping

Read More19th May 2025 - LNG Retrofit Market Sees Revival Amid Regulatory Pressures

In 2024, a notable development in the maritime sector was the renewed interest in LNG retrofits, driven by shipowners seeking immediate carbon reduction solutions to meet tightening regulatory demands. Over 305 LNG-fuelled vessels were ordered last year, representing roughly 14% of global newbuild orders and significantly outpacing alternatives like methanol and ammonia.

In 2024, a notable development in the maritime sector was the renewed interest in LNG retrofits, driven by shipowners seeking immediate carbon reduction solutions to meet tightening regulatory demands. Over 305 LNG-fuelled vessels were ordered last year, representing roughly 14% of global newbuild orders and significantly outpacing alternatives like methanol and ammonia.

Although LNG offers a viable near-term compliance pathway, the report cautions that deeper decarbonization efforts will be required in the longer term. Persistent challenges include methane slip and uncertainties around the availability of bio- and e-LNG. Still, with zero-emission fuel infrastructure in early stages of development, many operators view LNG as the most practical retrofit solution currently available.

Supply chain readiness remains a key concern. The report highlights that without improved collaboration among engine manufacturers, fuel system providers, and shipyards, conversion lead times could exceed 18 months. Recent amendments to the MARPOL Annex VI NOx Technical Code are expected to ease certification hurdles for converted engines, offering some regulatory relief.

Another constraint is the limited number of shipyards equipped to handle alternative fuel conversions. While the number has grown to about 16, primarily in China and the Middle East, current global capacity supports only around 465 vessel retrofits annually, well below the anticipated peak demand of more than 1,000 conversions per year.

Despite a modest pace of retrofit orders in 2024, engine designers are actively preparing for rising future demand. The shorter lead time of retrofit projects compared to newbuilds suggests that more retrofits, targeted for completion in 2026 and 2027, may be announced as early as 2025. LNG (liquefied natural gas) reduces shipping emissions primarily by replacing traditional marine fuels like heavy fuel oil (HFO), which are more carbon-intensive. Here's how LNG helps cut emissions:

- Lower CO2 Emissions

- Up to 20-25% reduction in CO2 emissions compared to HFO.

- LNG has a higher hydrogen-to-carbon ratio, resulting in less carbon dioxide per unit of energy when burned.

- Virtually Eliminates Sulfur Oxides (SOx)

- LNG contains almost no sulfur, so it virtually eliminates SOx emissions - a major cause of acid rain and respiratory problems.

- This helps ships comply with IMO's 0.5% global sulfur cap and emission control area (ECA) regulations.

- Significantly Reduces Nitrogen Oxides (NOx)

- When used in low-pressure dual-fuel engines, LNG can cut NOx emissions by up to 90%.

- This helps meet Tier III NOx regulations in ECAs.

- Particulate Matter (PM) Reduction

- LNG combustion produces far fewer particulates than HFO or marine diesel oil (MDO).

- Lower PM emissions are beneficial for both air quality and human health.

In Summary

LNG can significantly lower local air pollutants and reduce greenhouse gas emissions, making it a practical near-term option for shipping decarbonization. However, its role in a net-zero future depends on managing methane slip and scaling up renewable LNG alternatives.

#Protea #Emissions #Monitoring #CEMS #FTIR #Gas #Analysers #Shipping #Marine #Carbon #Capture

Read More12th May 2025 - Approaches To Carbon Management & The UK Strategy

Carbon management technologies are designed to cut CO2 emissions from industries and power plants, and to remove existing CO2

Why It Matters

Carbon capture, utilisation, and storage (CCUS) is seen as essential for hitting global climate targets. Every scenario from the Intergovernmental Panel on Climate Change (IPCC) that limits warming to 1.5°C or 2°C includes carbon management to reduce both current and past emissions, especially from hard-to-decarbonise sectors.

Types of Technologies

Carbon management spans several methods, from engineered solutions to nature-based approaches:

- Bioenergy with Carbon Capture and Storage (BECCS) - Captures CO2 from biomass power generation and stores it underground.

- Biochar - A carbon-rich by-product of biomass pyrolysis that can be added to soil to lock away carbon.

- Nature-Based Solutions (NbS) - Includes reforestation and wetland restoration to absorb and store CO2 naturally.

- Point Source Capture - Captures emissions directly from industrial facilities and power plants.

- Enhanced Weathering - Speeds up natural rock weathering to absorb CO2 from the atmosphere.

- Direct Air Capture (DACCS) - Uses chemical processes to pull CO2 directly from ambient air for storage or reuse.

- Geological Storage - Stores captured CO2 in deep underground rock formations, a key part of the CCUS chain.

The Road Ahead

R&D is focused on making capture technologies more efficient and less costly. Large-scale pilot projects are testing their real-world effectiveness in industrial settings.

The UK’s Role

The UK is investing heavily in carbon management as part of its net zero strategy. It aims to capture 20-30 million tonnes of CO2 annually by 2030 through a mix of these technologies. Protea is a major commercial partner for UK and global based initiatives in respect to CCUS with more information at our dedicated resource location https://www.protea.ltd.uk/carbon-capture-and-storage-ccs.

#Protea #Emissions #Monitoring #CEMS #FTIR #Gas #Analysers #Shipping #Marine #Carbon #Capture

Read More6th May 2025 - 2025 Is a Crucial Year for Shipping Decarbonisation Post MEPC 83

Shipping powers the global economy, carrying over 80% of world trade—but it comes at a climate cost. The maritime sector is responsible for around 3% of global greenhouse gas (GHG) emissions, making it the sixth-largest emitter if it were a country. Efforts to decarbonise the industry have been underway for years, but 2025 marks a turning point. In April, the International Maritime Organization (IMO) was expected to adopt key measures to implement its climate strategy and move the sector toward net-zero emissions by 2050.

These decisions made at MEPC 83, the 83rd session of the IMO’s Marine Environment Protection Committee and the regulations agreed on will be formally adopted in autumn 2025 and are expected to come into force in 2027, applying to all IMO member states.

For many in the shipping industry, the top priority is regulatory clarity. While there's strong support for the IMO’s climate goals, companies are awaiting concrete rules—particularly on a global fuel standard and possible carbon levy. These will shape the industry's approach to alternative fuels and investment.

The main obstacle to decarbonisation is the cost gap between conventional marine fuels and low- or zero-emission options like green ammonia or e-methanol. Ensuring a fair transition is also key. The IMO’s strategy calls for a “just and equitable” shift that supports vulnerable countries and regions.

While the transition may raise trade costs, it also offers economic opportunities—especially for nations that can invest in clean fuel production and port infrastructure to support zero-emission shipping. The outcomes from the MEPC 83 meeting will be public domain and we will be expanding on the key elements in due course.

#Protea #Emissions #Monitoring #CEMS #FTIR #Gas #Analysers #Shipping #Marine #Carbon #Capture

Read More28th April 2025 - Scaling Up Carbon Dioxide Removals In The EU

EU scientific advisors are urging a rapid scale-up of carbon dioxide removal (CDR) to help fight climate change. Both natural methods, like reforestation, and technological solutions will be essential, according to the European Scientific Advisory Board on Climate Change.

CDR captures and stores CO2, helping offset emissions from hard to decarbonise sectors like cement production. It will also be crucial for reaching net-negative emissions in the future, the board said.

The report highlights the need to restore natural carbon sinks in EU land areas, which have declined by about a third over the past decade. While plants offer temporary CO2 storage, technologies like Direct Air Capture (DAC) can provide permanent storage in geological formations.

The board recommends binding targets for both short- and long-term removals, warning that CDR must complement (not replace) emission cuts. Caps on removals should prevent companies from using them as a loophole to delay reducing emissions.

The EU and Germany have proposed carbon management strategies that include CDR, as well as carbon capture and storage (CCS) and carbon capture and utilization (CCU). However, a fully functioning carbon management system in Europe is still a work in progress.

The European Scientific Advisory Board on Climate Change is an independent scientific advisory body providing the EU with scientific knowledge, expertise and advice relating to climate change. The Advisory Board identifies actions and opportunities to achieve the EU’s climate neutrality target by 2050. The Advisory Board was established by the European Climate Law of 2021 with a mandate to serve as a point of reference for the EU on scientific knowledge relating to climate change by virtue of its independence and scientific and technical expertise.

#Protea #Emissions #Monitoring #CEMS #FTIR #Gas #Analysers #Shipping #Marine #Carbon #Capture

Read More22nd April 2025 - The IMO Must Tighten Rules On Shipping Carbon Emissions

Most global trade relies on shipping, which accounts for about 3% of global climate emissions due to heavy fuel use. One of the simplest and most effective ways to cut these emissions is to slow ships down. A 10% speed reduction can cut a ship’s emissions by nearly 20%, even if more ships are needed overall. This strategy requires no new technology and can be implemented immediately.

Cutting fuel use also reduces other harmful byproducts, like health-damaging particulates and oily sludge, which is often illegally dumped at sea. It also lessens the toxic waste generated by exhaust gas scrubbers, a largely unregulated and growing source of marine pollution.

Few actions offer such broad environmental benefits. Recent IMO meetings must seize this moment to adopt bold climate measures, including a global low-GHG fuel standard and a levy on ship emissions, to steer the shipping industry toward a cleaner, fairer future. An IMO working group met in London recently to discuss strategies for cutting greenhouse gas emissions from shipping, including a potential carbon tax. While the IMO is looking to approve emissions reduction measures at its Marine Environment Protection Committee meetings in the Spring, it is yet to commit to a carbon levy.

Supporters of a levy disagree on the price. Some suggest $20 per tonne of CO2, the EU proposes $100, and the 6PAC+ group of island nations advocates for $150. Research from University College London indicates that a $150 starting price could generate enough revenue to fund the energy transition and support a fair, equitable shift for vulnerable communities.

#Protea #Emissions #Monitoring #CEMS #FTIR #Gas #Analysers #Shipping #Marine #Carbon #Capture

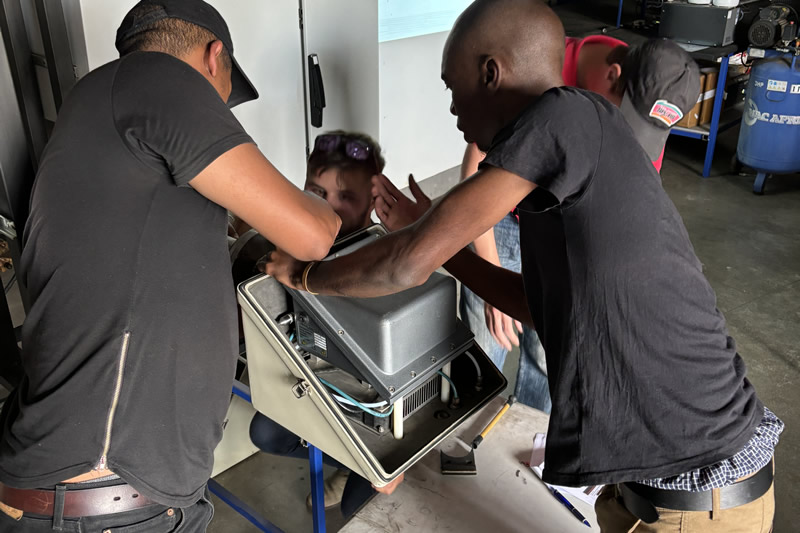

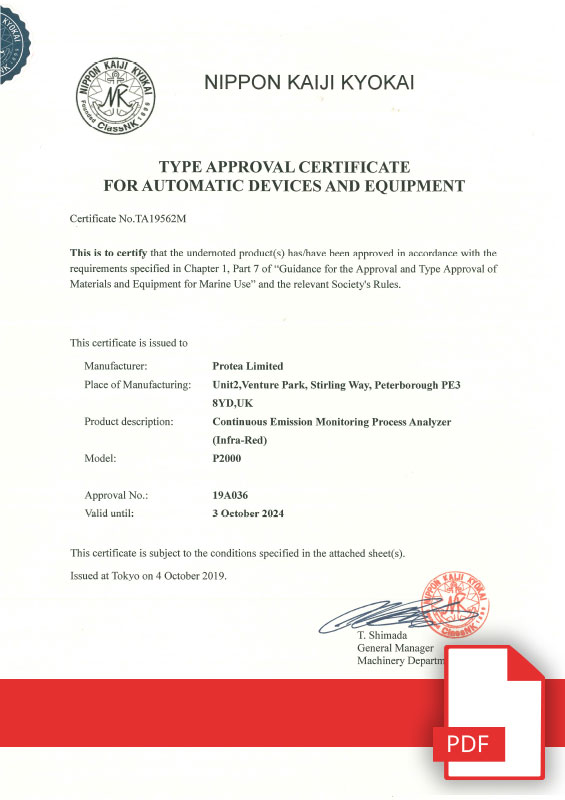

Read More16th April 2025 - DNV Statement of Compliance Achieved

Exciting News from Protea Ltd!

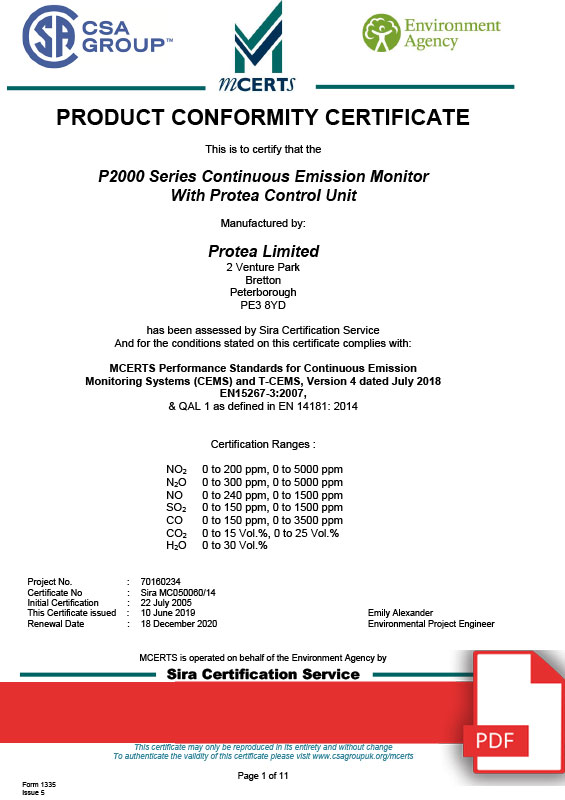

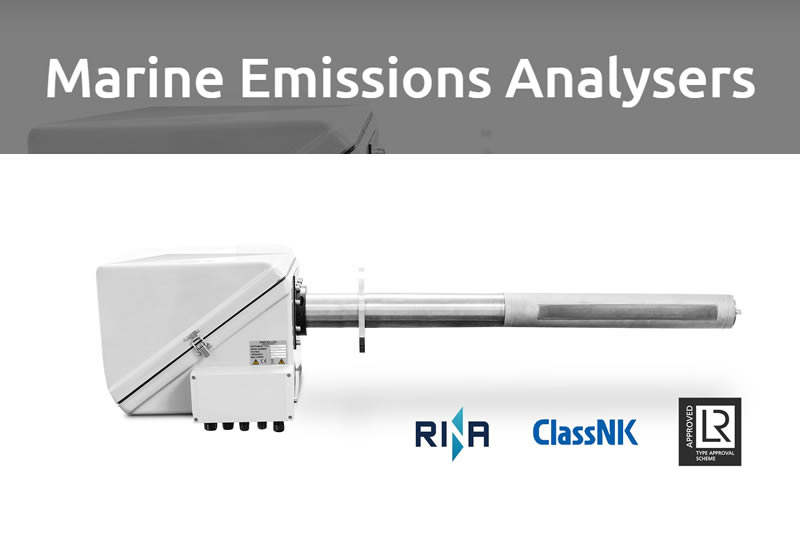

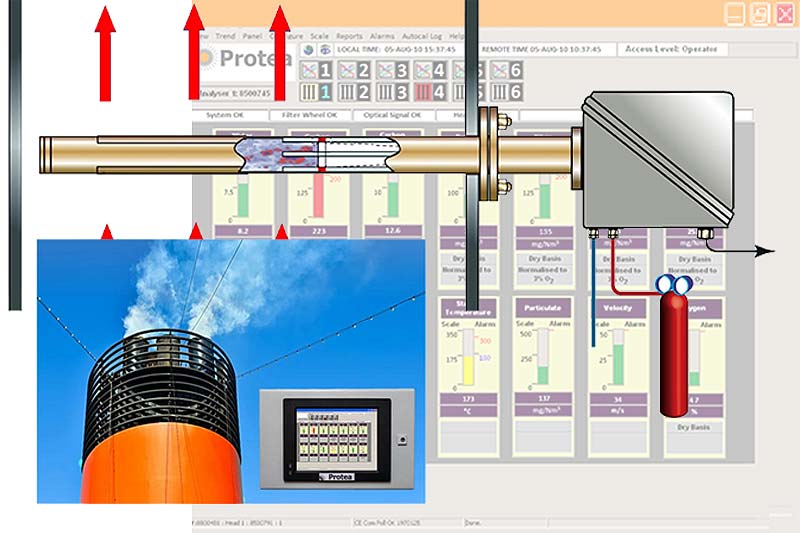

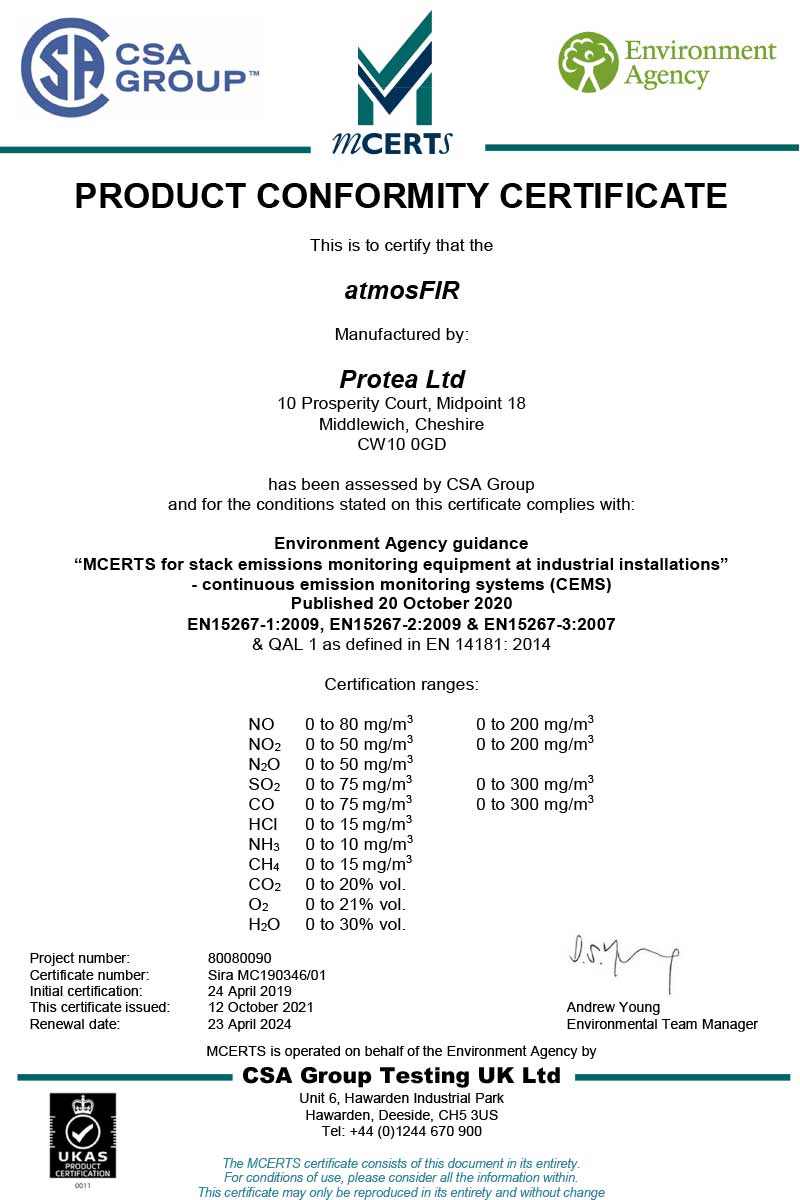

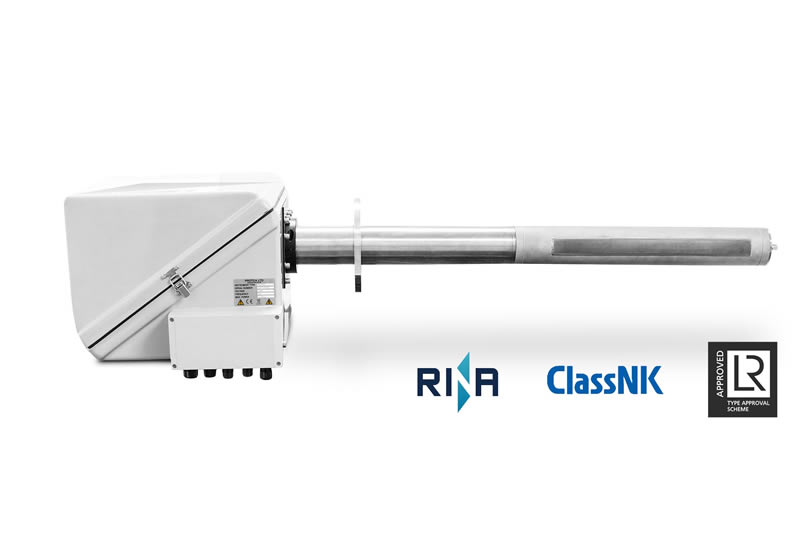

We are proud to announce that Protea Ltd has been awarded a Statement of Compliance by DNV for our Protea Marine Mass Emissions Systems for reporting into EU MRV!

This certification is a strong endorsement of our commitment to delivering high-quality, accurate, and compliant emissions monitoring solutions for the maritime industry. As global regulations tighten, our technology ensures that vessels stay ahead of environmental standards while enabling sustainable operations at sea.

Here's to a cleaner, more compliant future for maritime emissions!

#ProteaLtd #DNV #EmissionsMonitoring #MarineTechnology #Sustainability #Compliance #MaritimeInnovation

Read More15th April 2025 - Protea Featured in Spring Edition of Clean Shipping International

We’re excited to be part of the Spring edition of the Clean Shipping International, sharing our voice in the ongoing journey towards a cleaner, greener shipping industry.

As the maritime industry moves towards a low-emission future, we’re proud to share ideas and meaningful insights that go beyond just meeting regulations, by helping raise awareness and spark real change.

This issue highlights the people, technologies, and partnerships that are helping shape a more sustainable future for global shipping.

https://www.cleanshippinginternational.com/csi-magazine/

#CleanShipping #SustainableShipping #Spring2025 #CleanSeas #MaritimeInnovation #GreenFuture #Protea

Read More14th April 2025 - Marine Scrubber Market To Reach 20 Billion US Dollars By 2031 With New Emission Rules

Ships are vital for global trade, transporting goods across oceans. Their engines, however, emit significant exhaust gases. Marine scrubbers and exhaust gas cleaning systems are used to reduce these emissions. The marine scrubber market includes the production, installation, and maintenance of these systems.

According to Allied Market Research, the market was valued at $4.9 billion in 2021 and is projected to reach $20.3 billion by 2031, growing at a CAGR of 16.2%. Stricter global environmental regulations, especially in Europe and North America, are driving demand for cleaner technologies and emission control systems.

In the U.S., the EPA enforces major environmental laws like the Clean Air Act and the Pollution Prevention Act, focusing on reducing hazardous air pollutants. By technology, wet scrubbers accounted for nearly 90% of the market in 2021 and are expected to remain dominant, driven by strict emission standards. However, dry scrubbers are projected to grow fastest, at a CAGR of 22.6%, due to rising demand in Asia-Pacific, North America and Europe.

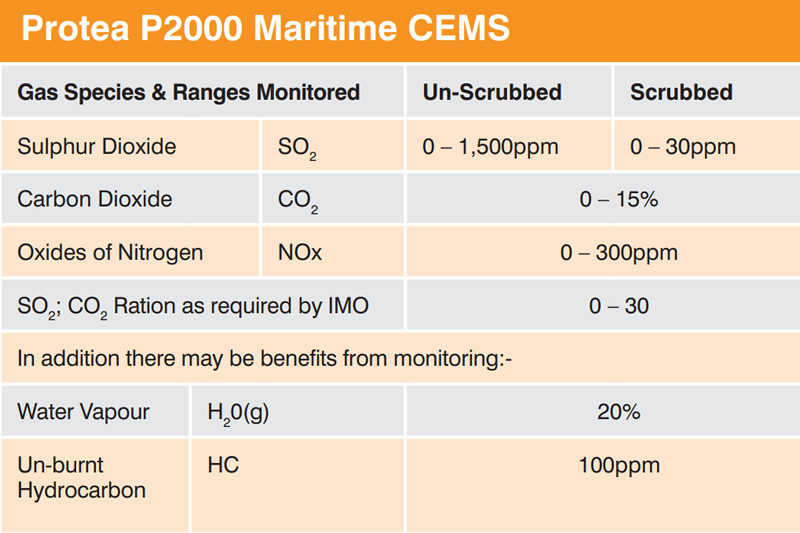

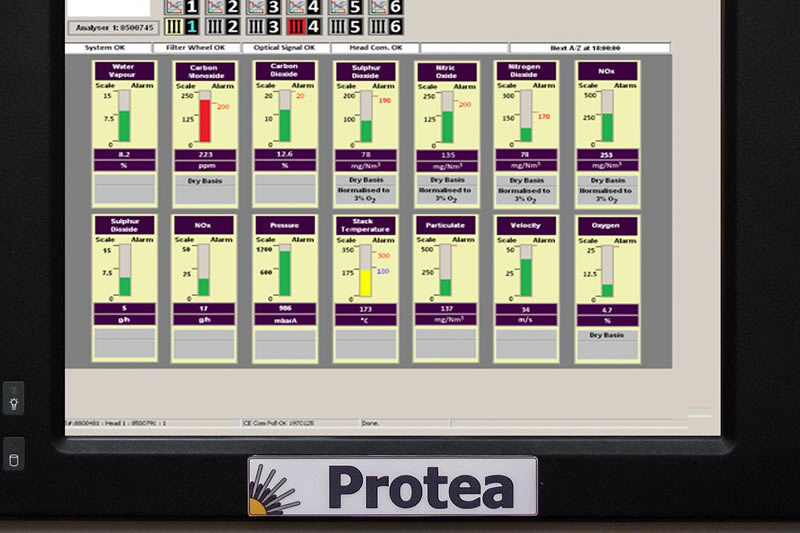

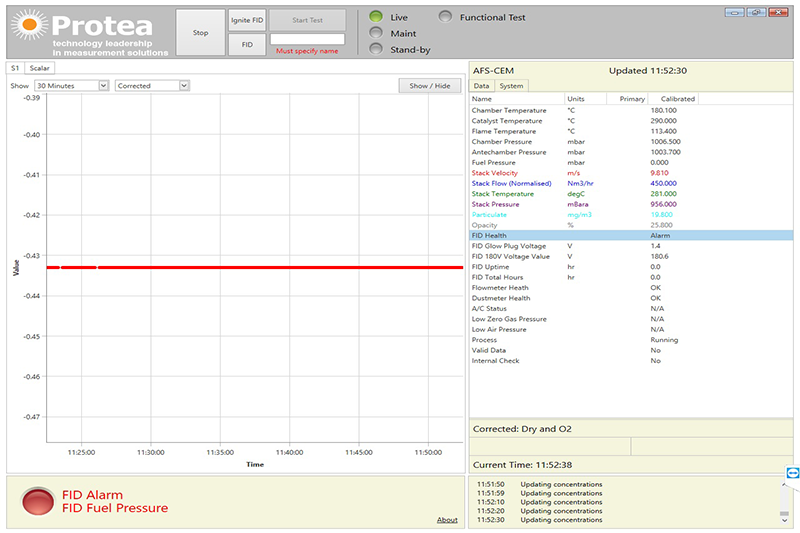

By application, bulk carriers held the largest share in 2021, as they transport key raw materials like coal and grain. The cruise segment, focused on passenger comfort and entertainment, is expected to grow fastest at a 21.0% CAGR through 2031. The Protea 2000 emissions monitoring system is approved for the analysis of exhaust gases from the engines and boilers of ships and offshore rigs. Robust and with proven reliability, up to six gases can be measured including SO2, CO2 and NOx.

#Protea #Emissions #Monitoring #CEMS #FTIR #Gas #Analysers #Shipping #Marine #Carbon #Capture

Read More9th April 2025 - Protea Exhibits at Cem Middle East in Bahrain

We’re excited to announce that Protea is exhibiting at the CEM Middle East Conference in Bahrain! Come and meet us at Stand 52.

- Event: CEM Middle East

- Location: Bahrain

- Stand: 52

- Date: 8th-10th April 2025

We’ll be showcasing our latest product range in emissions monitoring. Whether you're looking to enhance compliance, improve process efficiency, or explore the latest in gas analysis technologies, our team will be there to connect and engage.

#CEMMiddleEast #Protea #EmissionsMonitoring #EnvironmentalTechnology #ProcessAnalysis #BahrainEvents #CEM2025 #CleanAirSolutions #Stand52

Read More8th April 2025 - Protea Attending CEM Middle East 2025 In Bahrain

Protea is making an impact at CEM Middle East 2025 in Bahrain from 8th to 10th April exhibiting at Stand 52. The CEM Middle East Conference and Exhibition on Emissions and Air Quality Monitoring will be taking place in Bahrain on the 8th-10th April 2025 at the Gulf Hotel and Convention Centre in Manama. The CEM Middle East exhibition will follow on from over 35 successful CEM Air Emission and Air Quality meetings that have been organised since 1997.

Don't miss this opportunity to explore our cutting-edge CEMS technology, learn how our solutions are applied in real-world industries and connect with our expert team on Stand 52 at the Bahrain International Exhibition Centre. Let us talk about emissions monitoring, innovation, and the future of environmental compliance. We will be here, ready to connect.

#Protea #Emissions #Monitoring #CEMS #FTIR #Gas #Analysers #Shipping #Marine #Carbon #Capture #CEMMiddleEast

Read More1st April 2025 - Ankersmid M&C at M+R Antwerp

Our trusted distributor, Ankersmid M&C, is at the M+R Exhibition in Antwerp, displaying our P2000 equipment! If you’re attending on the final day, be sure to stop by, take a look, and ask any questions to their knowledgeable team.